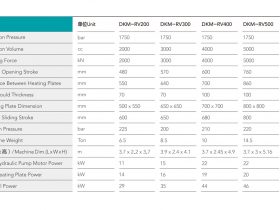

- Applications

Suitable for Natural Rubber(NR), Nitrile Butadiene Rubber(NBR), Ethylene Propylene Diene Monomer(EPDM), Isobutylene Isoprene Rubber, etc. Two series are applicable in automobile, electric power and civil industries, e.g. rubber vibration absorber cylinder cushions, sealing parts, cable connectors and pipe connectors, etc.

- Characteristics

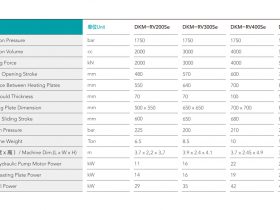

RV Series

- Designing and optimizing of the plasticization system and injection

system are leaded by German engineers, the screw can be suitable for variety of materials, excellent performance even for extra high hardness material.

Particularly design for injection system can disassemble the accumulator - Quickly, facilitate to replace the seals and remove the material.

- Imported double-layer, High pressure and high temperature resistance

thermal insulation plates reduce 40% energy consumption, much more energy saving and more reliable. - Dual-seal clamping cylinder, avoid oil leakage.

- Adopt American high pressure pump and German hydraulic valve, ensure the stable and reliable hydraulic system.

- The injection stroke and clamping stroke adopt the world famous electronic ruler with accuracy of 0.05%.

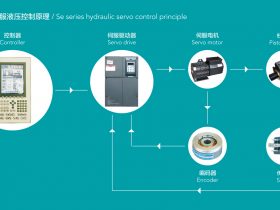

Se series

- Energy saving, Low operating cost: The output of servo system is completely based on the required pressure and flow of machine, eliminating the reactive energy consumption, only 40% electricity consumption as comparing with equal proportional pressure and proportional flow control method.

- High repeatability precision: Adopting high precision pressure sensor, servo motor, high precision encoder, during operation, the pressure and flow are real time comparison, control error is controlled by specific PID controller.

- Swift dynamic response: High performance pump and synchro servo motor, fast response, short deceleration distance, high speed and stability.

- Instant power consumption management system: Optional electronic wattmeter, instant power consumption data will be processed by B&RS98 controller for machine performance and production analysis.

- Low noise: Creating a quiet environment for you even in the condition of high pressure clamping and injection.