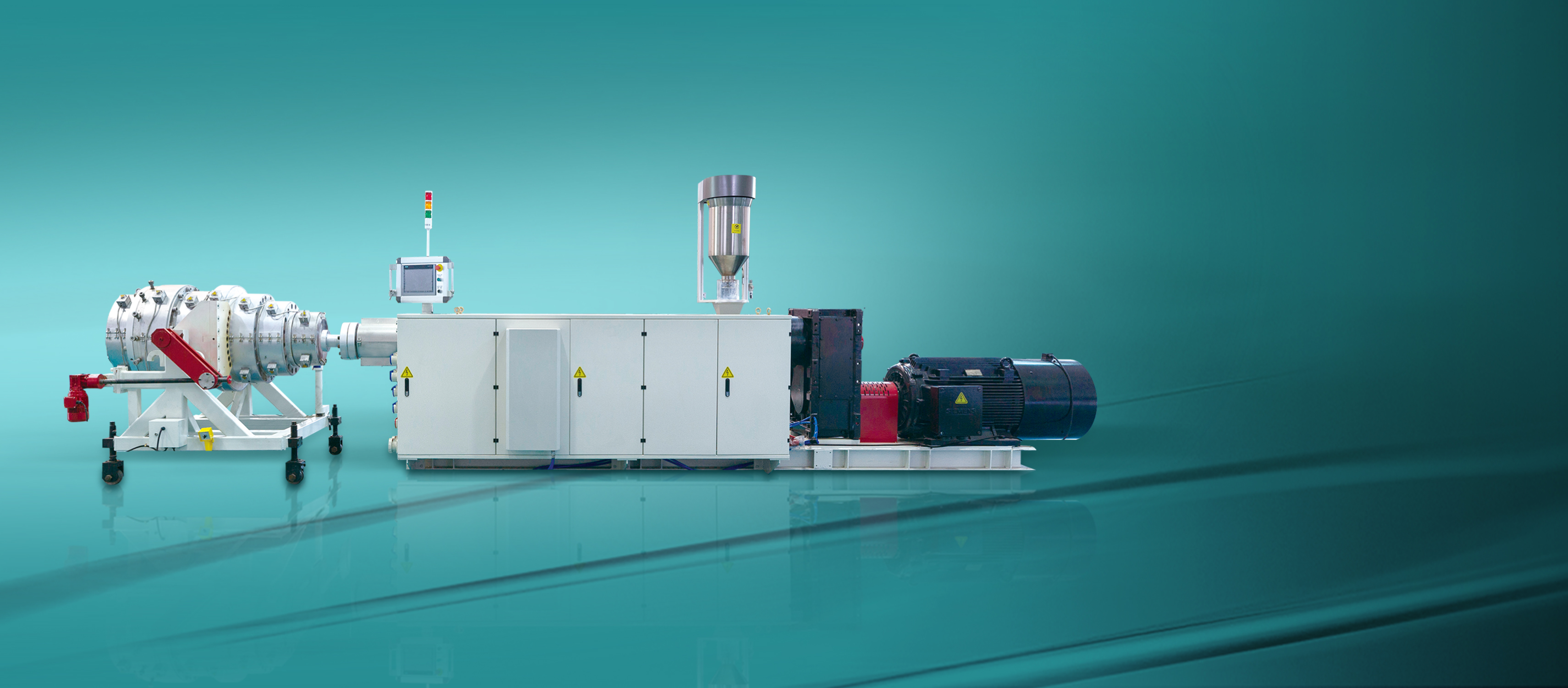

Extrusion Line

Since 2004, Dekuma Extrusion Line has been committed to providing customers with high-quality pipe extrusion machines for PE, HDPE, PP, PPR, PE-RT, PE-x, PVC, PA, TPV…

Pipe diameter range from 6mm to 2800mm.

Hot sales: EV6 Automotive Tubing Extrusion Line, Mircoduct Extrusion Line …

READ MORERubber Injection Moulding Machine

Dekuma always adhere to the Germany technical standards, the core components and all raw materials are selected and processed in strict accordance with German standards, so that Dekuma products have high reliability and stability.

Hot sales: Auto Sealing Strip Jointing Machine, Rubber Track Production Line, Rubber Insulator Production Machine …

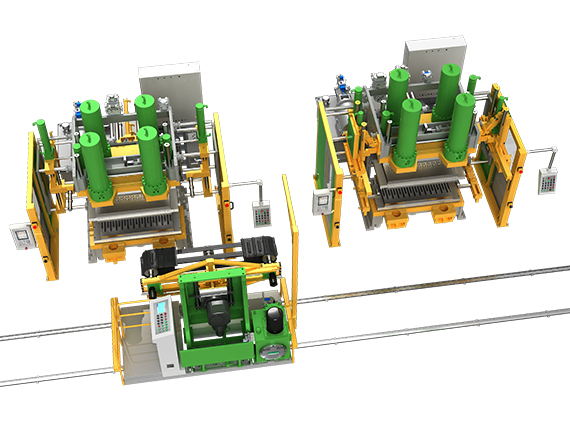

READ MOREHydraulic Press

Cosmos Press founded in 1979. In the past decades, the Company has developed a completed product range, the pressing pressure range from 1 to 5000 tons with dozens of specifications, pressing motions including down-stroke, up-stroke, downward ejecting, upward ejecting and composite type.

Hot sales: Braking Plate Press Machine, Grinding Wheel Press Machine, Auto Part Press …

READ MORE

Rubber Track Production Line

Suitable for agriculture tracks, construction tracks, military tracks and snowmobile tracks. High automation, energy-saving, hydraulic precise control multiple actions, longer product life, and smart control product quality.

READ MOREFrame Type Double Action Servo Driven Hydraulic Press

Used for metallic material in deep drawing, forming, stamping and blanking process, such as water sink and auto parts, etc.

READ MORE

Telecommunication Cable Microduct

Dekuma single screw extruder is suitable for telecommunication cable micraduct, which adopts the latest German technology that guarantees the superior machine performance.

Read more

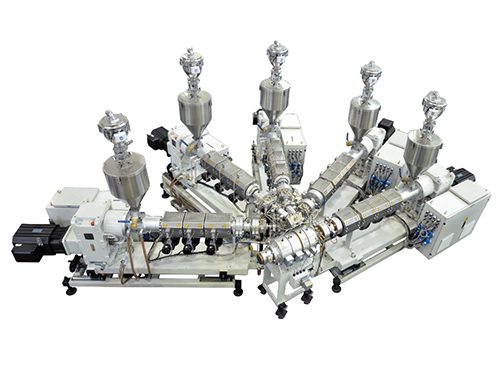

Single/Multi Layer PE-RT/PE-X Floor Heating Pipe

Dekuma single screw extruder is suitable for PE-RT/PE-X floor heating pipe, which adopts the latest German technology that guarantees the superior machine performance.

Read more

PVC Pipe

Optimized design of the ventilating parallel counter-rotating twin screw, can be applied to different formulations of CPVC / UPVC materials. Having the advantages of low wear, low energy consumption, high efficiency, and uniform stability extrusion.

Read more

PE/PPR Pipe

Dekuma single screw extruder is suitable for PE/ PPR Pipe, which adopts the latest German technology that guarantees the superior machine performance.

Read more

Rubber Track

Rubber Track Production Line is suitable for agriculture tracks, construction tracks, military tracks and snowmobile tracks.

Read moreLiquid Silicone Rubber Product

Liquid Silicone Rubber Production Line is suitable for electronic components, insulator, arrester, cable accessories, sealings, infant care, food container, kitchen articles and sports industry, etc.

Read more

Press-on Solid Tyre

Press-on Solid Tyre Rubber Production Line is suitable for solid tyre diameter 9~22 inch.

Read more

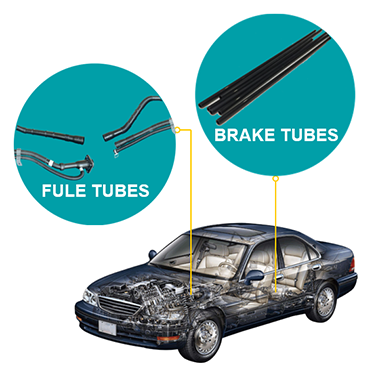

Automotive Nylon Tubing

Nylon(PA) multi-layer composite pipe of automotive fuel system has been a kind of light weight, high performance and environmental friendly pipeline product widely used in automobile fuel system in the world recently. Automotive nylon pipe, mainly used for oil supply, oil return, air brake and glass cleaning etc.

Read more

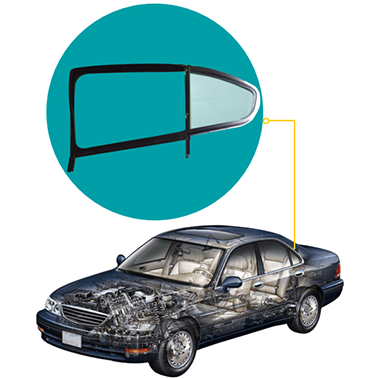

Auto Glass Seal

RV-Se Series (250 T~400 T injection machine for auto glass seal) are suitable for TPV, TPE, flexible modified PVC and other raw materials manufactured by injection molding, widely used in the autoglass encapsulation of industry, especially suitable for the overall TPV glass edge of large size car window with precise injection volume.

Read more

RV & Se Series-Rubber Injection Moulding Machine

Suitable for Natural Rubber(NR), Nitrile Butadiene Rubber(NBR), Ethylene Propylene Diene Monomer(EPDM), Isobutylene Isoprene Rubber, etc. The two series are applicable in automobile, electric power and civil industries, e.g. rubber vibration absorber cylinder cushions, sealing parts, cable connectors and pipe connectors, etc.

Read more

Rc Series-Rubber Injection Moulding Machine

Rc series are mainly applicable in automobile, such as precise rubber parts, auto glass seal, sealing, skeleton oil seal and TPU parts, etc.

Read more

RA Series-Rubber Injection Moulding Machine

Suitable for Silicon Rubber, Ethylene Propylene Diene Monomer.

Read more

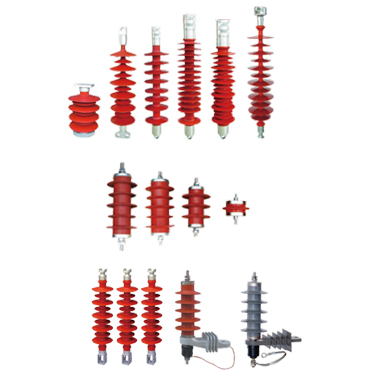

RT Series-Rubber Injection Moulding Machine

Suitable for HTV silicone rubber to produce long-rod insulators, hollow core bushings, arresters, cable accessories and switch gear.

Read more

RI Series-Rubber injection moulding machine

RI series are suitable for general insulators and rubber products.

Read moreWhat They Say

Testimonials

Our Service

Focus on your need

Turn-key Solution

Depend on the Cosmos group’s long history experience, we understand the end products and market well, we can provide customers with a complete turnkey solution.

Read moreTechnical Support

With the technical foundation established by German engineers, a strong technical team with more than 30 engineers, and technical cooperation with South China University of Technology, Dekuma has the leading technical in the Rubber and plastic machinery industry in China. We provide comprehensive technical support to our customers.

Read moreService Support

Professional service team provides fast response and excellent support including 12 months warranty period, operation training, machine testing and commissioning at Buyer’s site.

Read moreOur Teams

The best to best

Technical team

Technical engineerTechnical foundation established by German engineers, our strong technical team with more than 30 engineers, and technical cooperation with South China University of Technology.

Service Team

Service engineerProfessional service team provide operation training and T & C of machine at Buyer’s site.

Sales team

Senior industry expertSales team who understand market and user requirements. Patiently answer your inquiries, and provide you with the most suitable solution

Call us +86-769-22667200 |

|

Contact us via mail info@dekuma.com |