#02

#03

#02

#03

Traditional brake pad backing plate hydraulic press is particularly noisy during production process,seriously affecting the working conditions of workers.

Not to mention wearing earplugs when starting work, the factory will often be complained by nearby residents.The working hours are very limited.

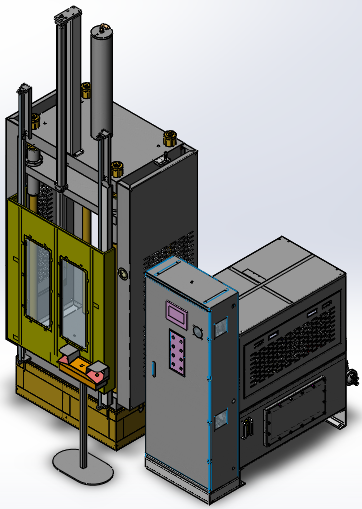

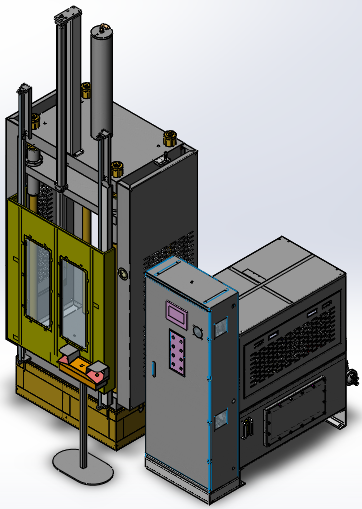

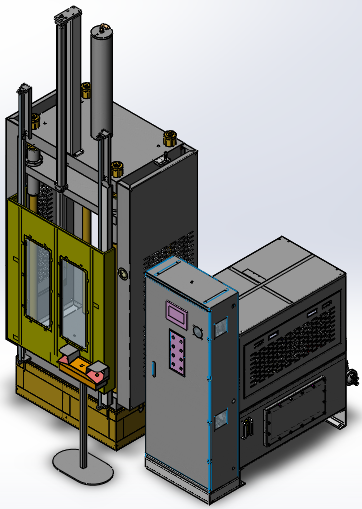

According to the process characteristics,DEKUMA adopts hydraulic press with a servo motor driving oil pump to replace the traditional punching machine to produce brake pad backing plate.

Traditional punching machine has no acceleration and deceleration functions.Instead, it produces by the collision and extrusion of the upper and lower dies. It will make noise when colliding.

But the servo press can slow it down before the collision.Then try to reduce the noise of the collision as much as possible.

Our steel backing hydraulic press can be almost silent when in standby.The impact force during operation can also be much lower than that of traditional punching machine.Reducing the working noise from a maximum of 120dB to 75-78dB,workers don’t need to wear earplugs when using DEKUMA steel backing hydraulic press.

If you feel better, your work will definitely be easier.The product qualification ratio will also increase.And the problems such as difficulty in recruiting workers or limited working hours due to loud noise will be easily solved.

Recently, DEKUMA’s upgraded and optimized new RC480 automated rubber track production machine has been commissioned, and successfully exported to South Korea and arrived at the customer’s factory.

This customer is one of the largest auto parts manufacturers in South Korea, with production bases in many countries and regions, such as China, Europe, Southeast Asia and South Korea headquarters where DEKUMA’s rubber track machines are widely used.

DEKUMA has been cooperating with this customer for more than 10 years, and continuously improves equipment during the cooperation, and creating greater value to the customer.

Today, let’s see how DEKUMA’s rubber track production machines meet customer needs and keep improving.

Excellent performance of DEKUMA’s rubber track production machine

High degree of automation, reducing labor intensity and manpower requirements

In the past, the traditional production of rubber track required manual feeding, demolding and product retrieval. Generally, the production of a rubber track of several hundred kilograms required 3~4 people to work together.

#02

Overcome steel wires week links, and improve the service life of track

Advanced non-dynamic clamping and vulcanization structure reduces energy consumption in production process

#04

Highly intelligent operating system realizes simple operation

Abstract: This paper analyzes the production process of PTFE compression molding, and summarizes the causes why conventional pressing pressure and pressing process are easy to cause product defects and scraps.

To solve the problems of surface patterns, cracks, discoloration, hidden cracks, etc., the hydraulic press team of Dekuma has developed a precision servo hydraulic press for blank pressing of PTFE powder product, and solves the problem for customers from the root.

01 Introduction to PTFE Properties

PTFE, known as the “king of plastics”, features many excellent properties including colorless, non-toxic, wide temperature resistance, chemical inertness and low coefficient of friction.

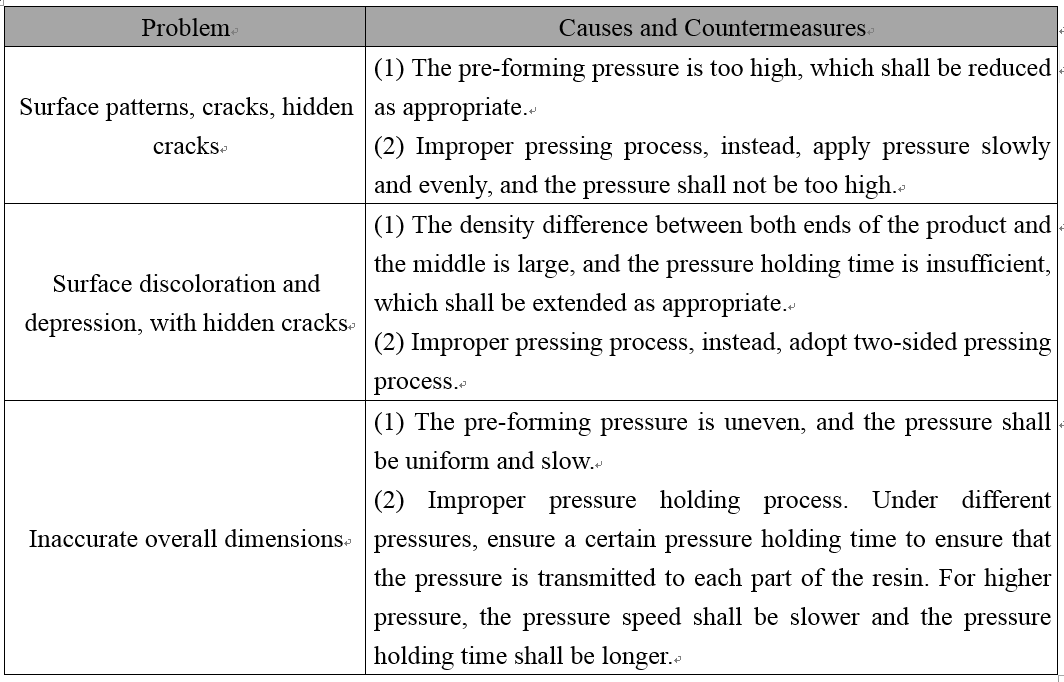

It serves as one of the important materials that are indispensable to all industrial sectors, e.g. automobile, national defense, machinery, chemical industry, electronics and other industries. It can also be made into PTFE pipes, rods, belts, plates, etc.

02 Commonly Used Methods of PTFE

The most common method is compression molding when processing products with PTEE.

The process of compression molding goes roughly as follows: raw material inspection → mashing and sieving → measuring → molding → semi-finished product inspection → sintering → cooling → finished product inspection → packaging.

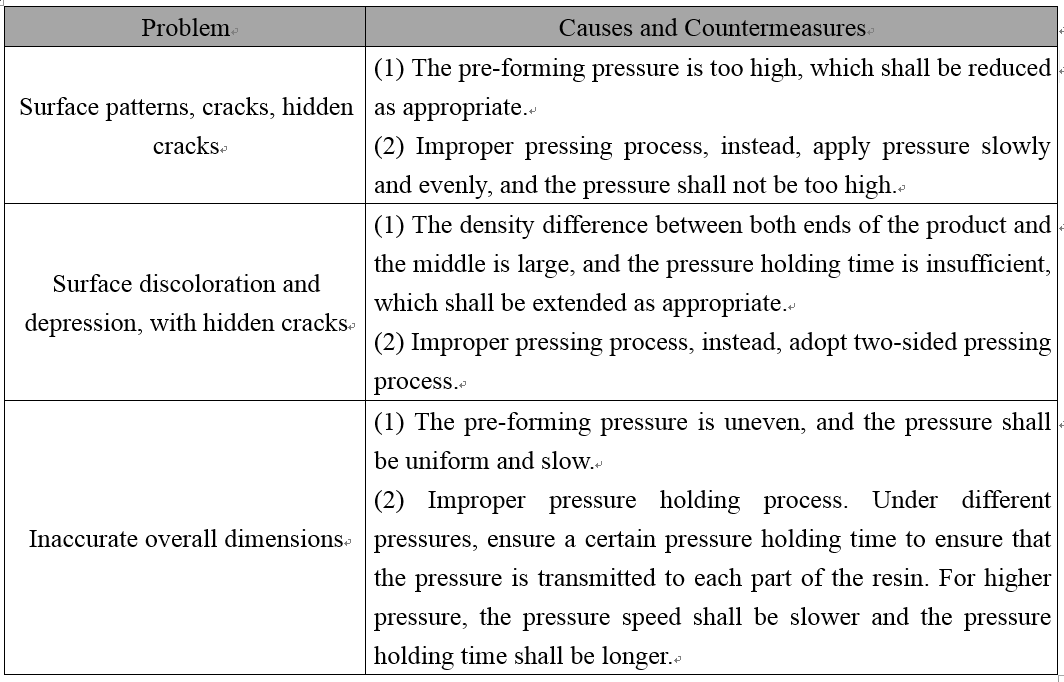

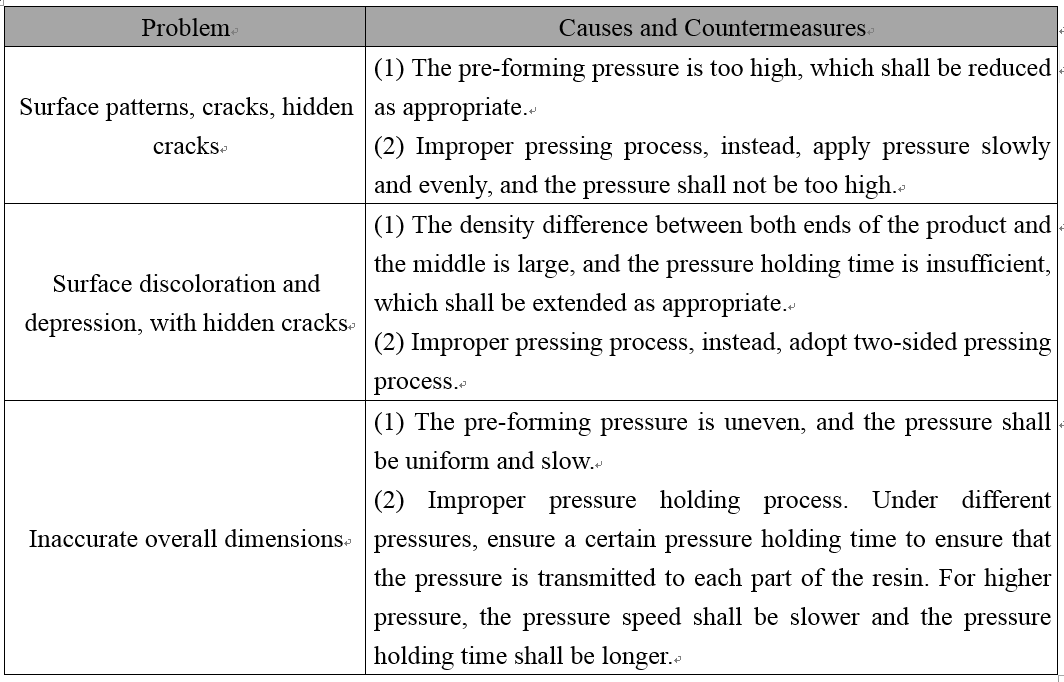

After investigation on the common problems encountered during production of PTFE compression molding, it can be found that the improper operation of pressing pressure and pressing process may easily cause product defects and scraps, and the unstable pressure output serves as the main reason for cracks.

On the basis of understanding the customer’s process, the hydraulic press team of Dekuma has developed a precision servo hydraulic press for blank pressing of PTFE powder product, and solves the problem for customers from the root.

03 Advantages of PTFE Powder Blank Precision Molding Machine

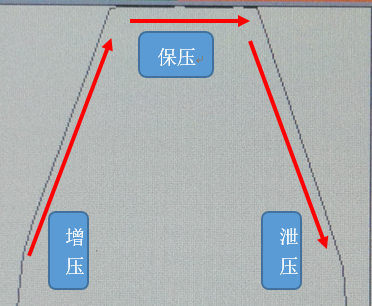

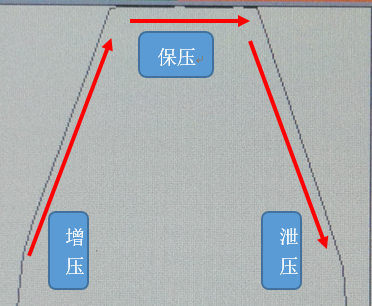

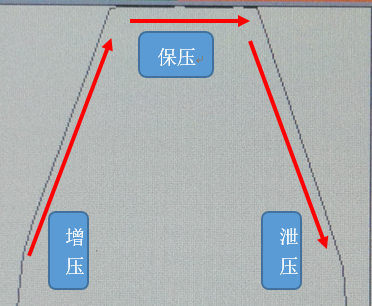

(1) Slow Pressure Rising and Controllable Time

For powder compression, the time will significantly affect the effect of product molding. In case that the speed is too fast, exhaust will be insufficient, which may easily cause problems such as surface patterns, cracks, and large differences in density between both ends and the middle.

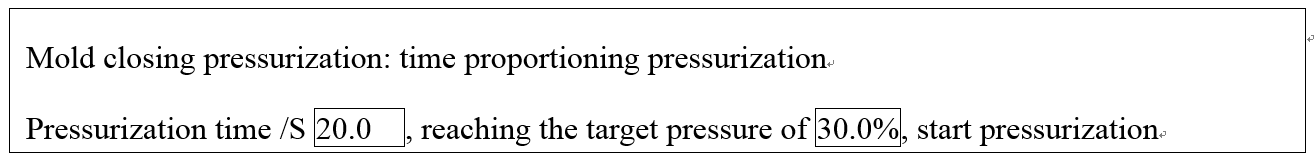

For the time control of pressurization, the hydraulic press adopts servo motor oil pump hydraulic system to solve the problem. Under the cooperation of hydraulic pressure and electricity, it has developed a controllable function of slow pressurization based on the set pressurization time, and the pressurization time is controllable from several seconds to dozens of minutes.

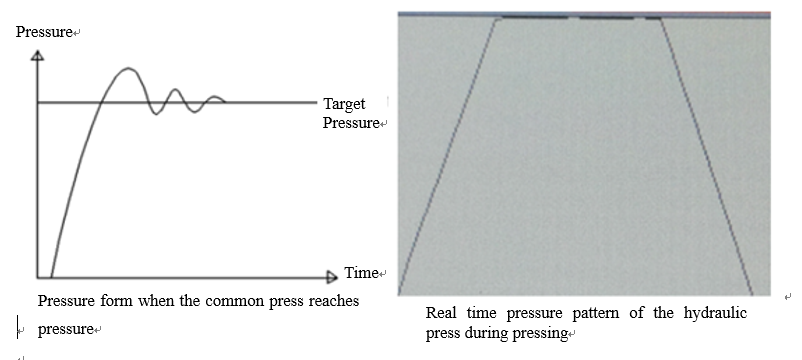

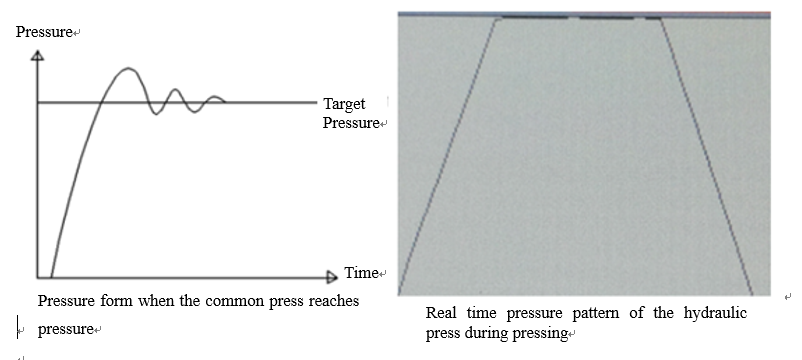

(2)Almost no pressure impact and fluctuation in pressurization stage

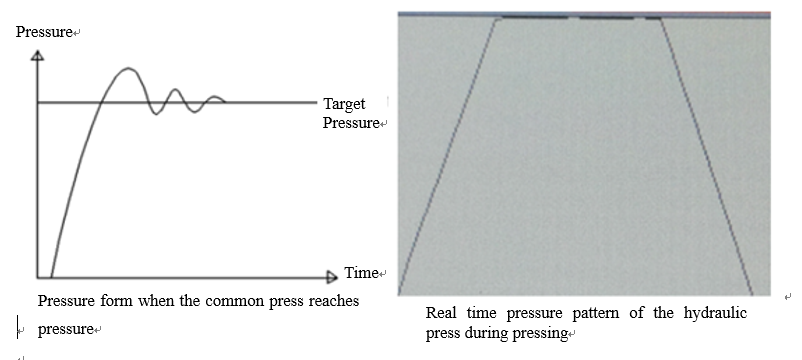

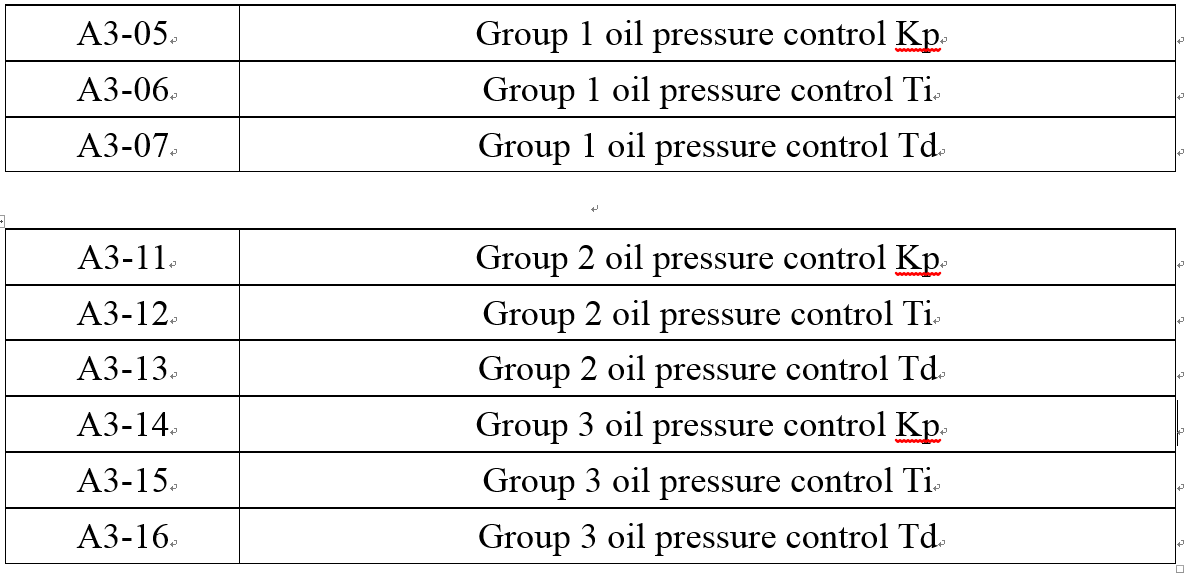

At the critical point of signaling pressure, most common hydraulic presses will experience the process of overshoot – fallback – stabilization due to inconsistent pressure repeatability each time.

Under the cooperation of server and plc program, the hydraulic press can control the critical point of signaling pressure well under the high sampling frequency and high-speed scanning cycle.

Thanks to the research results of hydraulic team of Dekuma for years, the set target value can be achieved under cooperated control of the server and the plc program. In the pressure holding stage, the pressure fluctuation is controlled within 1 bar, which can also maintain long-time operating of oil pump without damage.

Due to the specific characteristics of PTFE powder, after the initial pressurization to the set pressure and entering the holding pressure stage, the volume can still be compressed continuously. Once the volume is compressed, the pressure shall be reduced and the press will supplement pressure. Therefore, the pressure holding stage of PTFE product serves as a process of hydraulic system continuous pressure dropping and supplementing.

The stability of hydraulic press is realized based on years of application experience. Under the perfect coordination of high response of servo hydraulic PID and discharge flow of hydraulic oil circuit, the pressure fluctuation reaches almost zero.

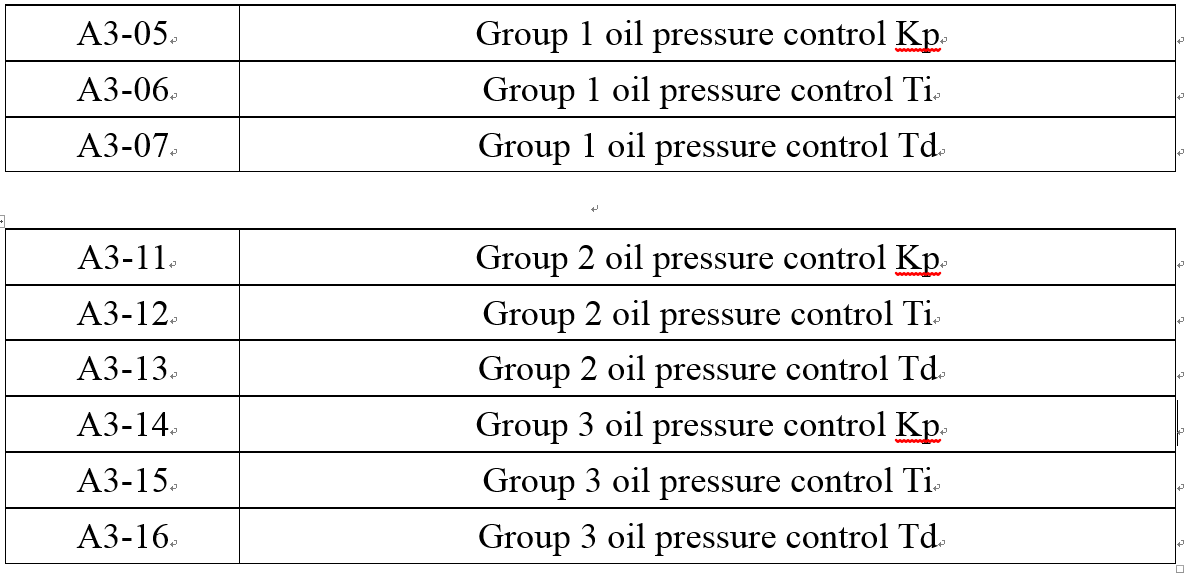

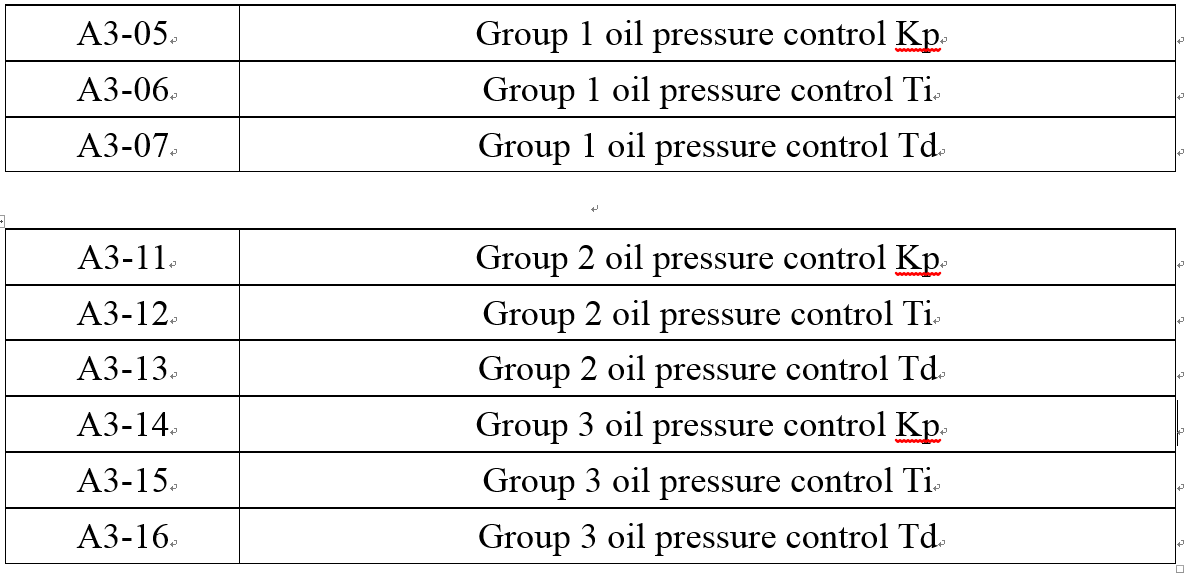

For accurate pressure output, the hydraulic press engineers continuously optimize the hydraulic system and program. In application of servo system, sometimes a single PDI parameter is often not sufficient for the pressure range of the whole area. With the PID parameters set with low pressure, it will be still not applicable when reaching medium and high pressures.

After finding this situation in practical application, the hydraulic press combines with years of application experience, adopts multiple sets of PID parameters, corresponding to the multi-stage signaling pressure of the hydraulic press, and avoids the inapplicability of a single PID parameter to different pressure stages.

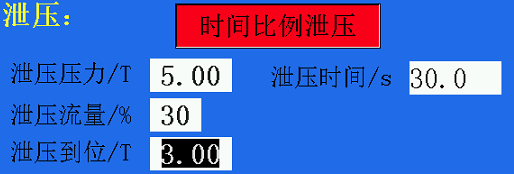

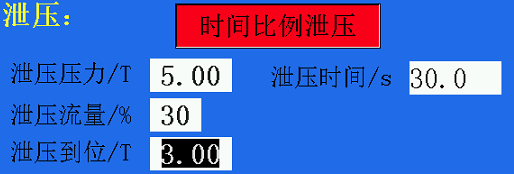

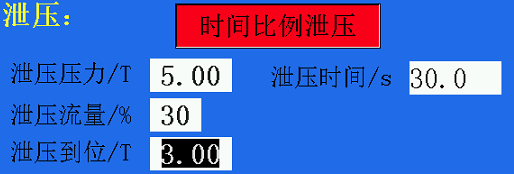

(3)After completion of pressing, the pressure relief time is controllable

For pressing of PTFE powder blank products, sometimes the pressure holding time takes dozens of minutes, with the purpose of obtaining a blank product with uniform density after reaching a certain compression ratio. However, after reaching the pressure holding time, in case of pressure relief instantaneously for some products, it is easy to cause the quality problem of hidden cracks inside the product.

To solve the problem of pressure relief, the hydraulic engineers have developed the function of slow pressure relief process and controllable time, and the pressure relief time can be controlled from several seconds to dozens of minutes.

For this, the pressure relief process can be considered as an inverse process of pressurization. During pressure relief, the pressure is output according to the time ratio for the purpose of reducing pressure until the final pressure relief in place. Conventional hydraulic presses have no such function.

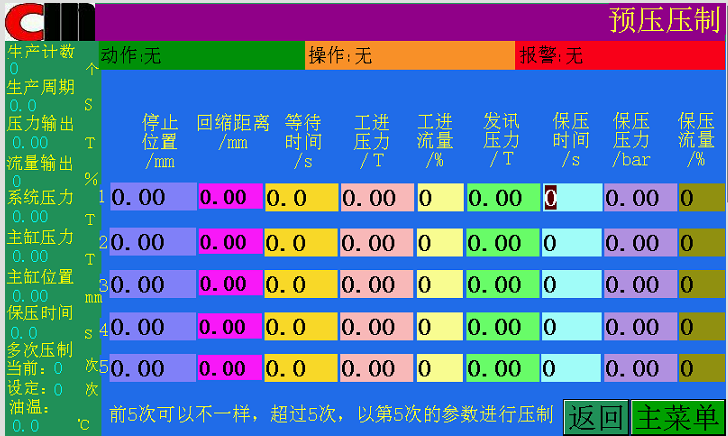

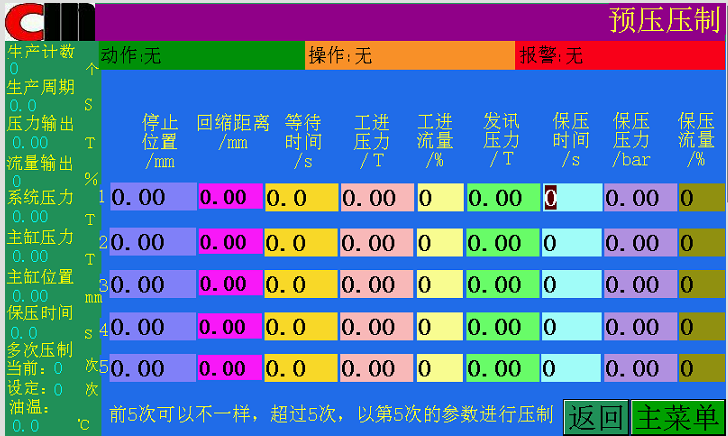

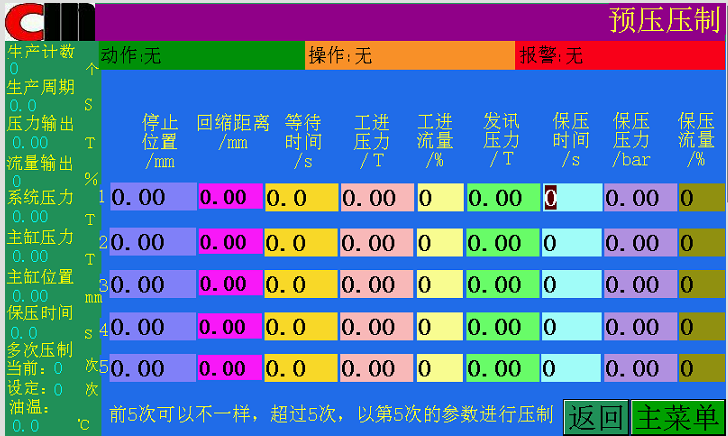

(4)Convenient setting of process parameters

Adopt PLC + touch screen + servo drive control, for intuitive and efficient setting of technological process and parameters.

Most PTFE blank molding methods require two-sided pressurization + product demolding, and one product forming requires pressing twice + demolding once. However, the pressing parameters of the three times are not the same, and common hydraulic presses require repeated manual filling of different parameters three times.

Based on the special process of PTFE, the hydraulic press has compiled the parameter setting method for this process, allowing the customers to input parameters that conform to the product for one time, and the pressing can be completed with only operation controller. The operation is simple and fast, which reduce the probability of errors, improves reliability, and significantly reduces the technical threshold of operators.

For products that require to maintain pressure and exhaust for a certain period of time under different pressures to ensure transmission of pressure to all parts of the resin, it provides a free parameter setting function. (As shown in figure below)

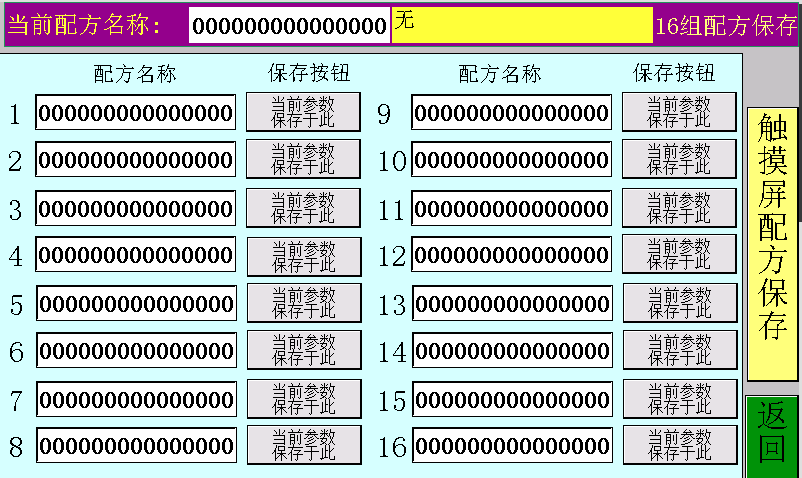

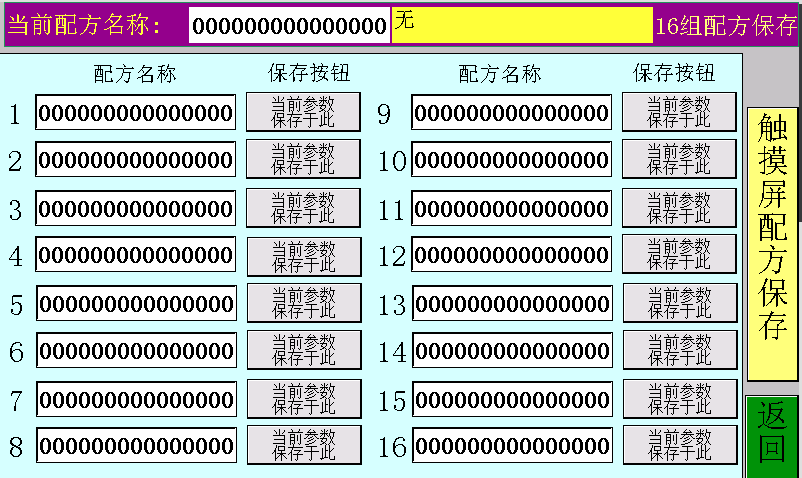

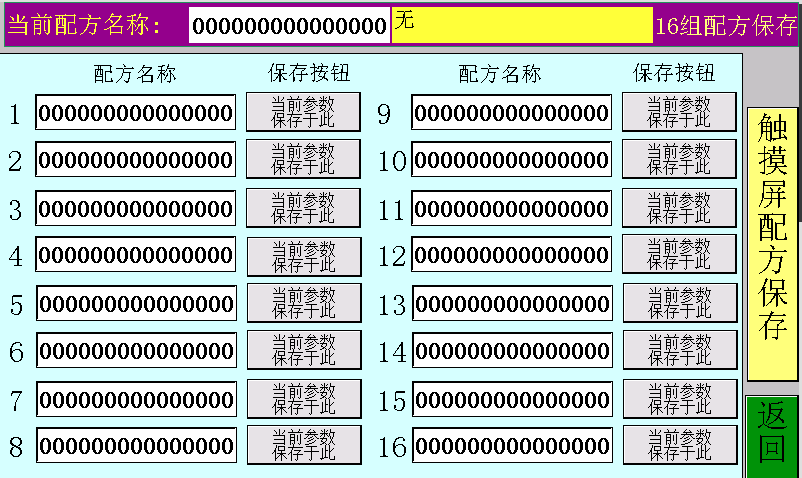

For commonly used product parameters, after completion of debugging and passing inspection, it can be saved as a recipe, which supports one-key save and recall. (As shown in figure below)

(5)Energy saving and environmental protection

Common hydraulic presses produce large noises when working, which can easily pollute the production environment and affect the health of operators. The Datong hydraulic press adopts a servo motor as the power source, whose noise level is only about 70 decibels when working, and is almost silent under standby state. When operating, the torque is output according to the size of immediate load. The power loss is small, which can save 30%-50% of electric energy compared with common hydraulic presses, with significant energy saving effect.

Note that the pressing and holding time of PTFE powder blank products is long. For high precision, the user shall basically maintain the pump on and holding pressure. In this process, the servo motor system of the press only needs a dozen or so percent of output to conform to the pressure holding requirements. The hydraulic system produces less heat, reduces the cooling cost, and extends the service life of oil pump.

Common hydraulic presses require full speed output when the pump is on and pressure is holding. The actual utilization rate is only about 10%, and the machine is doing useless heating work for the rest time. The power loss is large, the energy utilization rate is low, and the oil pump service life of each hydraulic component is reduced.

04 Conclusion

For PTFE powder molding, accurate and stable pressure serve as the key factor to molding; for investment income, machines with energy-saving, energy conservation and environmental protection and high-utilization features are the key to cost recovery and realization of benefits; for operators, simple and efficient operation mode is the key point; the hydraulic press meets all the above key points, which can meet customer needs, and help customers solve problems from the root.