Abstract: This paper introduces an environmentally-friendly and efficient servo hydraulic press for production of backing plate of brake pads launched by Cosmos Presswhich widely used in the brake pad industry in past few years.

Keywords: automobile brake pad, production of steel backing, automatic production.

1. Difficulties in production process and special equipment for backing plate

Our investigations in Guangdong, Jiangsu, Zhejiang, Hebei and Shandong district reveal that the production of backing plate has the following features: the steel plate is relatively thick, generally 4-6mm, while the backing plate is generally designed with rivets and holes for installation on the caliper, therefore, the production processes are various and accuracy requirement is high.

At present, in the industry, the conventional punching process is the main production method. The main production equipment are mechanical presses. Some factories will use traditional hydraulic presses in some processes.

The control of quality is difficult in the production process with mechanical press and traditional hydraulic press. The production with mechanical press has a great impact on the service life of die. There is no domestic machine manufacturer to produce precision pressing equipment for backing plate. Some customers with high quality requirements will use imported fine blanking press which improves the quality of backing plate. However, the fine blanking press with price of several millions greatly increases the production costs. In addition, it is not conducive to flexible production with different specifications and in small batches, and affect the competitive advantage of enterprise.

Furthermore, the mechanical press generates great noise during punching process, so it is not environmentally friendly. Workers must wear ear protector for protection, the worse working environment cause difficulties in recruitment. With the improvement of urbanization, a factory which generates noise and is not environmental friendly is often complained, so the working time is greatly limited!

2. Introduction to functional characteristics of Cosmos servo driven hydraulic press

Automobile brake pads are vulnerable parts with large production volume. With the rapid growth of the automobile market and the increase of automobile owner, all automobile brake pad manufacturers are expanding their plants to increase productivity, and new manufacturers are also running into the market.

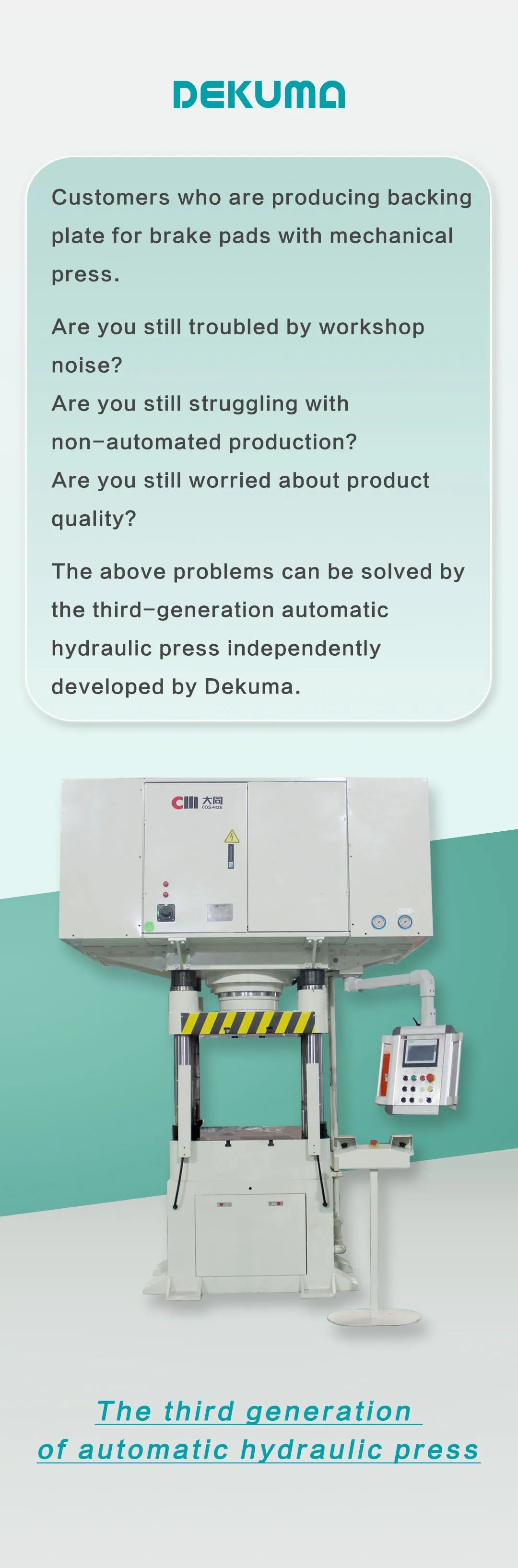

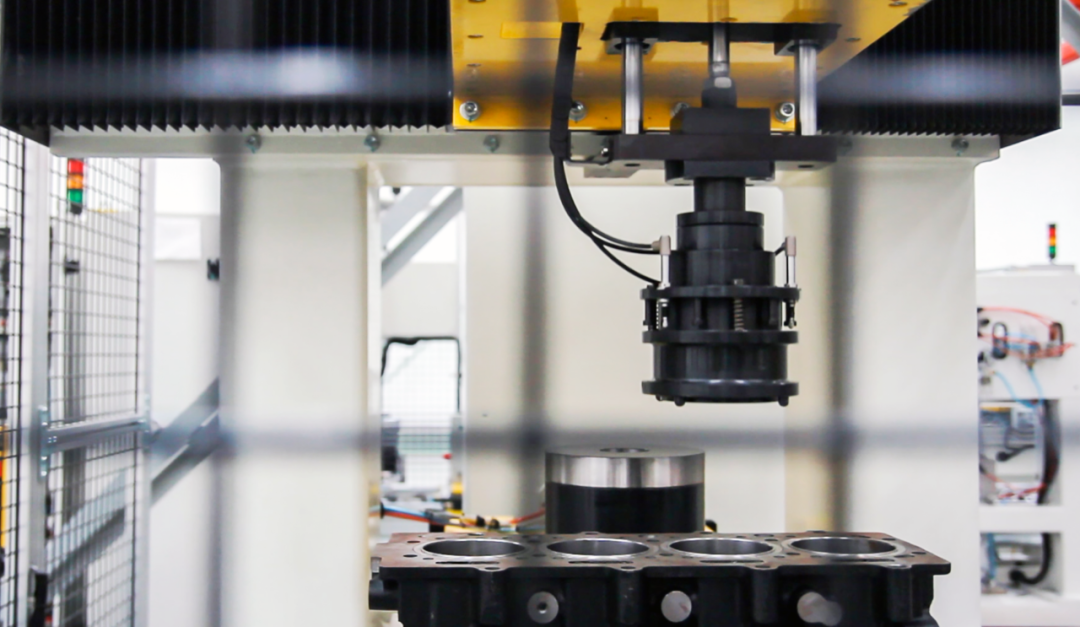

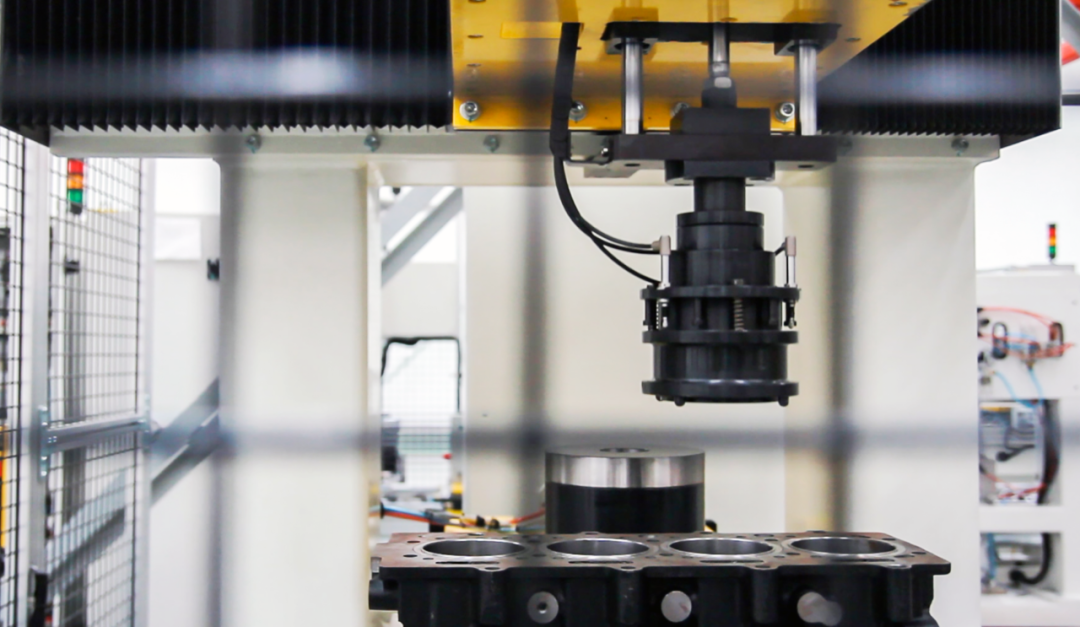

To meet the needs of customers, Cosmos Press, under the support of the group’s strong R&D strength, has launched a special environmentally-friendly, low noise level and efficient servo driven hydraulic press for production of backing plates. The machine matched with the molds can fully cover the typical production processes of backing plates including 1.chamfer forming; 2.stamping; 3.pin forming and 4.fine stamping;

At the beginning of the design, the characteristics of “large quantity and low price” of backing plate production were known. On the premise of meeting the function, the costs of the equipment should be minimized, and the redundant design should be well controlled, to ensure that each kilogram of steel of the equipment is useful, and each component is appropriate at this position.

3. Advantages of Cosmos servo driven hydraulic press

3.1 Compact structure, easy operation, and automation

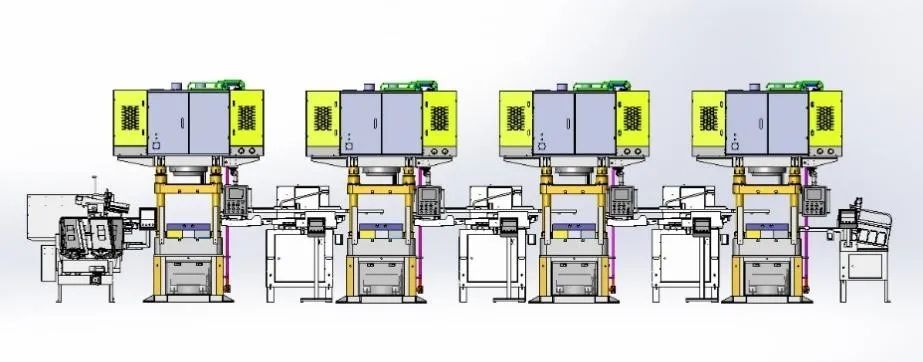

This machine is different from the traditional small table hydraulic press. Its hydraulic electrical system is reasonably designed and arranged on top. It is compact, has no obstacles around the machine, and is convenient for operation and installation of the mold. It does not affect the placement and handling of products. It is deeply favored by the workers on site. There is no obstacle around. Therefore, neither single machine automation nor multi-machine automation is affected. The production mode of multi-machine automation device reduces the manpower.

3.2 Rigid and lightweight machine body structure

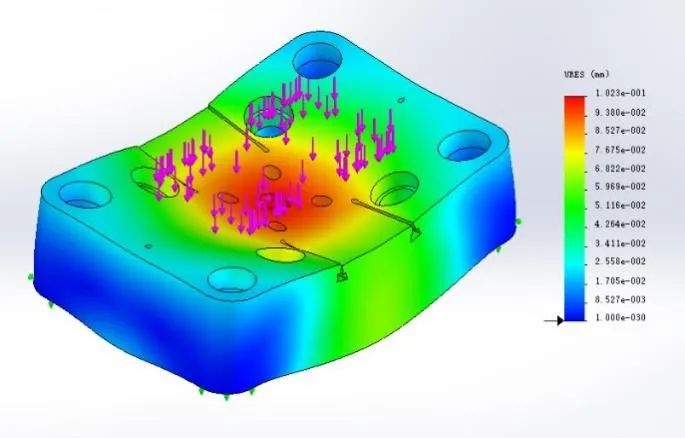

The machine body structure avoids the “short, flat and fast” method of the small table machine, that is, three platens are made of heavy steel plates to achieve the purpose of rapid design and production. The three platens composed of top platen, moving bolster and fixed bolster are made of high-quality nodular cast iron. The reinforcement structure adjusted by finite element analyses is more reasonable, enhance good strength and small stress deformation, and has more optimized weight and safety factor ratio. Therefore, it avoids the phenomenon of “the wool coming from the sheep”, i.e. customers spending more money on machine weight.

3.3 Low noise level, environmentally-friendly, high-speed and stable hydraulic system

3.3.1 Low noise level and environmentally-friendly

The optimized servo motor hydraulic pump system only generates approximately 70dB to 80dB noise level during operation, and almost doesn’t generate noise in idle time, which greatly reduces the noise problems in the working environment. The operator enjoys moving from mechanical press workshop to servo driven hydraulic press workshop. To a certain extent, it also reduces the pressure of labor recruitment.

3.3.2 Pressure and position accuracy

The moving position and the pressing pressure are controlled and detected by precision linear transducer and pressure sensor. The pressure sensor matched with servo driver control can realize stepless regulation of working pressure. The working pressure for production of large and small backing plates can be set according to demand, which improves the quality and stability of products, and improves the “uncontrollable pressure and vulnerable mold” during punching operation; the pressing pressure can provide data support for new product development according to the size and accuracy requirement of product.

3.3.3 High-speed response

The highlight of the hydraulic system is used of imported Rexroth directional valve matched with the domestic mature two-way large-flow cartridge valve technology which not only realizes high-speed response to meet the production efficiency, but also reduces the manufacturing costs of the high-speed hydraulic system. The specially designed cartridge valve system reduces the resistance of the hydraulic oil flowing at a high speed, reduces the calorific value and the energy consumption, ensures the long-term high-speed response without stuck phenomenon, and ensures 24 hours stable and automatic production of press hydraulic system installed with oil cooler.

3.3.4 Control system

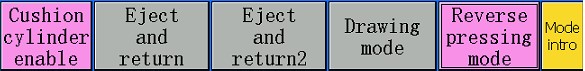

The “PLC+ touch screen + servo driver” control can realize the intuitive and efficient setting of the process flow and parameters. The flexible pressing process is adopted. Based on current backing plate production process and years of experience, Cosmos Press’ machine contains most of the pressing technologies of production process in the market. It can do the pressing process that cannot be completed by the mechanical press, realize the flexible and multi-purpose use of one machine, reduce the expenses and floor areas of production line, and lower the production costs.

Instant and effective action prompts

3.3.5 Unique finishing process structure

Based on the requirements of production process of backing plate, the machine is designed with a special cushion cylinder structure for finishing process. The sheared edge zone and dimensions of backing plate produced by the customer’s mold with the cushion cylinder structure, can reach the precision requirement from main engine factory. A special proportional pressure valve is equipped on the two-way cartridge valve to realize the floating blank holding force during finishing. By adjusting the floating blank holding force, the sheared edge zone of finished backing plate can meet the requirements. Besides, under the support of the floating force, the geometric dimensions of the previous processes of the backing plate will not be affected. A certain leveling effect will also be achieved.

Equipped with a special mold frame, it can be used in the reverse finishing process, that is, the ram cylinder is used for pressing and leveling, and the cushion cylinder is used for finishing. This process action is applicable to products requiring high leveling force.

The finishing process meets the quality requirements of backing plates. Three or four machines are combined to form an automatic line for production of backing plates. Customers do not have to spend millions on purchasing imported machines. It reduces the production costs of products, realizes the flexible production with different specifications and in small batch, and improves the product competitiveness.

4. Other advantages

4.1 Energy saving

The servo motor as the power source of machine. In working, it outputs the torque according to the real-time loads. Its power loss is small, 50% less than the traditional induction motor fixed with displacement pump, and at least 30% less than the traditional induction motor with variable pump.

4.2 High productivity

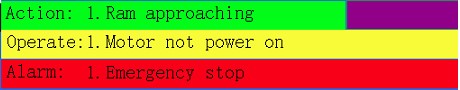

Its productivity is equal to that of mechanical press. It can complete punching action within 1.3s-1.6s and complete finishing action within 1.7s-2.3s.

5. Conclusions

Its successful development has solved three problems in traditional brake pad production process with mechanical press, i.e. “difficult recruitment & low per-capita productivity, noisy and high energy consumption”, relieves the pressure of environmental protection of an enterprise in production, greatly improves the product competitiveness, creates profits for users, and makes contributions to the development of automobile industry in China.

1. Hardship in plastic machinery development

Since 2002, with China’s reform and opening-up policy, its economy rapidly grew and there was a strong demand for rubber and plastic machinery and equipment from different industries. The Chinese manufacturing industry’s knowledge and technical skills in the rubber and plastic machinery industry was well behind other foreign countries’, causing local domestic manufacturing companies to be dependent on imported machines. European and American equipments were more advanced, but they were expensive. Shipments were also slow and after-sales services were mostly unresponsive. If the machines or components were damaged when received and required re-ordering, the lead-time usually took at least one or two months for another shipment. This greatly hindered China’s rapidly growing manufacturing industry.

Some European manufacturers realized the opportunity for business development in China, and decided to invest and set up factories in China. Only a few of them were successful in setting up their manufacturing facilities and developing their own brands in China, most of them were unable to take any market shares in the Chinese market due to a lack of understanding of Chinese law, culture, the market, etc.

2. Awakening of the industry

Amid the industry’s development, we questioned if a machine with high performance and reasonable production cost was really impossible, and whether high-end rubber machines can only be used in niche markets.

For several years, the core management team of Cosmos Machinery Enterprises Ltd. (Cosmos) had been searching for solutions.

Cosmos is a Hong Kong listed company with more than 40 years of experience in machine manufacturing, industrial product trading, and manufacturing of plastic products. Cosmos has been one of the market leaders in machine manufacturing in China Mainland, with an ample source of quality customers and suppliers. Our strong sense of brand awareness and quality control have demonstrated asuccessful model more capable than our mainland counterparts. In addition, Cosmos has an advanced and extensive capacity forproducing and processing rubber machinery as well as the rich experiences in collaborating with some international partners. More importantly, the core team in Cosmos could communicate well and exchange ideas with Europe counterparts, which would help us understand and develop necessary knowledge and skills in advancing our technology.

With Cosmos recognizing the importance of manufacturing its rubber machineries on its own, it then built a machining center in the 1990s, which has possessed a strong processing and production capacity.

In order to enhance the competitiveness of China’s rubber and plastics machinery and equipment industry, and reduce the dependency on imported equipments, it was important to develop the ability to build our own high-end equipments, that is why Cosmos’ executives have conceived a uniquesolution.

DEKUMA GmbH Deutsche Kunststoff Maschinen

With the continuous competitive environment across all industries, the competitive edge of Dekuma’s standard was being challenged, and more importantly, both domestic and foreign customers urgently needed customized equipment to enhance their competitiveness.

In order to satisfy the upgrading needs of customers, Dekuma turned its attention to the niche market segments in 2012 and began actively paying attention to theirneeds by continuing the technological innovation and continuous research and development.

Although there was still a gap between Dekuma’s equipment and imported equipment, the gap was narrowing rapidly. Comparing with foreign branded equipment, some of Dekuma’s most significant competitive edges are rapid response, effective technical exchanges in early stages, timely equipment delivery, equipment installation and optimization, and quick solutions to problems encountered by customers… These characteristics could be the real solution for problems of efficiency encountered during the rapid development of all Chinese manufacturers.

Among different niche market application, Dekuma has been highly recognized by our users such as from automobile nylon tubing, rubber track, the microduct cables, hydraulic press for brake pad sectors thanks to our strong R&D, perseverance and our willingness to customize products for our clients.

6. China’s smart manufacturing journey

近日,畅销产品DEKUMA微管挤出生产线通过验收,实现多项性能突破!

DEKUMA微管挤出生产线远销欧洲、中东、东南亚等地,可生产用于光缆网络建设和扩建的硅芯管和集束管。自2011年推出以来,DEKUMA与客户合作,不断优化升级,打造四大优势:

01.高输出

6-14mm硅芯管DEKUMA微管挤出生产线生产速度可高于100m/min。

凭借DEKUMA高产量挤出主机、优化设计的多层模头、高性能下游设备、自主研发的PCC全线电脑控制系统和多年的细节优化,其生产速度实现了世界级速度。

02.高稳定性

在管材的高速生产中,生产线的各个环节都可能成为生产速度的瓶颈。

主机挤出量的波动,真空度的突然变化,甚至冷却中的摩擦,都可能随时中断管材的生产。

DEKUMA知道用户的想法并为用户考虑。在原有高品质挤出生产线的基础上,对微管的生产进行了针对性的优化,实现了生产速度的不断突破。

现在,100m/min 的速度仅仅是个开始。我们将继续挖掘DEKUMA挤出线的潜力,立志成为微管生产设备的最佳选择。

03.操作方便

先进的PCC电脑控制系统,实现全线自动化控制。

主机配有米重控制装置,实现生产速度和挤出量的自动调节。

收卷机配有积放架,并设计有自动换卷功能,使紧张的换卷工作变得轻松可控。

04.交钥匙解决方案

2011年,为满足意大利客户的要求,DEKUMA自主研发了该设备。

在与客户的不断合作中,德库玛逐渐加深了对微管生产需求的理解,并不断对设备进行优化升级。

DEKUMA已经掌握了微管生产的交钥匙解决方案,并取得了多项突破。挤出生产线可达到同类设备的世界一流水平。

微管挤出生产线不仅帮助意大利客户成为当地最大、欧洲领先的通信网络解决方案提供商,还成功协助沙特阿拉伯、埃及、南非、泰国等地区的客户从传统管材生产升级到微管生产.

随着通信技术的不断发展,特别是5G网络的高速普及,网络运营商需要增加新的光缆网络以满足用户日益增长的数据需求。城市大规模光缆网络的建设依赖于充足的地下管道资源。因此,通信管道管孔资源的短缺是不可避免的。

传统的扩管方式需要挖路,成本高,施工难度大。在国外,基于硅芯管和集束管的微导管和微光缆系统技术是解决“最后一公里”问题最流行的方法。德库马与国外客户合作开发的微管挤出生产线,为客户提供高产能、高稳定性、人性化操作的一整套解决方案,帮助客户轻松实现微管生产的转型和产能升级。

一、产业发展之痛

回到世纪之交的2002年…

随着中国改革开放,经济快速发展,中国对橡塑机械设备的需求量很大。当时,我国橡塑机械行业技术水平与国外的差距比今天大得多,国内企业对进口设备的依赖程度也比现在高。欧美设备虽然技术先进,但价格昂贵,订单周期长,售后服务响应慢。如果设备出现故障,则需要一两个月才能修复。对于飞速发展的中国制造业来说,这是一个“难以言喻的痛点”。

一些有远见的欧洲品牌直接到中国设厂,但由于对中国法律法规、当地文化和市场环境缺乏了解,大多面临各种“不适应”问题。有的靠着“天然免疫力”活了下来,有的在中国挣扎了几年后,只好“回家”。

2.觉醒之路

市场上总有先行者。

国内一些橡塑机械企业“灵机一动”,斥巨资在欧洲购买设计图纸,却受制于当时国内机械制造的材料、技术、管理、文化等因素。结果是两者之一——要么是公司严格按照图纸制造,成本高,产品性能与欧洲进口的设备相差甚远,要么是公司进行“选择性学习”一些创新,但设备与原始设备制造商的设备没有太大区别。

一些比较激进的企业直接从欧洲进口设备,将零部件一一拆装。但这种方式只能让他们了解外观和结构,而不是了解国外专业技术的技术精髓,包括材料技术、核心工艺和程序控制,即“知道怎么做,不知道为什么”。生产的设备“形状相似,但技术不同”。

我国橡塑机械行业继续混乱前行。

三、德国遗产的来源

COSMOS认识到自主加工能力的重要性,于1990年代建成加工中心,具有强大的加工和生产能力。

为提升中国橡塑机械装备行业竞争力,打造自主高端装备,逐步减少中国企业对进口设备的依赖,服务更多国内制造企业,科斯莫斯高层构想了独特的突破战略。

DEKUMA GmbH Deutsche Kunststoff Maschinen

2002年初,COSMOS的高层在德国成立了一个对中国文化和机械行业有着深刻理解的小型技术团队。经过一段时间的相互了解和协商,双方发现可以高度互补,并就长期合作达成共识。

在合作框架的指导下,欧洲团队首先在德国成立了一家名为“Dekuma GMBH”的小型科技公司(“Dekuma”是德语单词“German Plastic Machinery”前两个字母的缩写)。奠定了“德国遗产”的基础。他们很快就开始了 Dekuma 第一代橡塑设备的设计和开发工作。

COSMOS的高层之所以没有直接在COSMOS工作,而是将团队设在德国,是因为他们对德国研发“技术背景”的重要性有高瞻远瞩的认识。具有“德国血统”的设备只能在德国文化的背景下进行设计。

4.卓越品质的基础

虽然德库玛的设备与进口设备仍有差距,但差距正在迅速缩小。

与进口设备相比,德库马最重要的竞争优势是反应迅速,前期技术交流迅速,设备交货迅速,设备安装调试迅速,对客户遇到的问题快速、及时的解决——真正解决客户遇到的问题。中国企业在高速发展过程中的“效率困境”!

德库马针对汽车橡胶密封条角接机、橡胶履带机、汽车尼龙多层油管生产线、微型管道挤出生产线、汽车钢背专用机等细分市场极具代表性的专用机不断研发创新。在细分市场,德库玛的客户常说,不买进口机,就选德库玛。

或许这就是专注和专业的力量!

6、中国智能制造