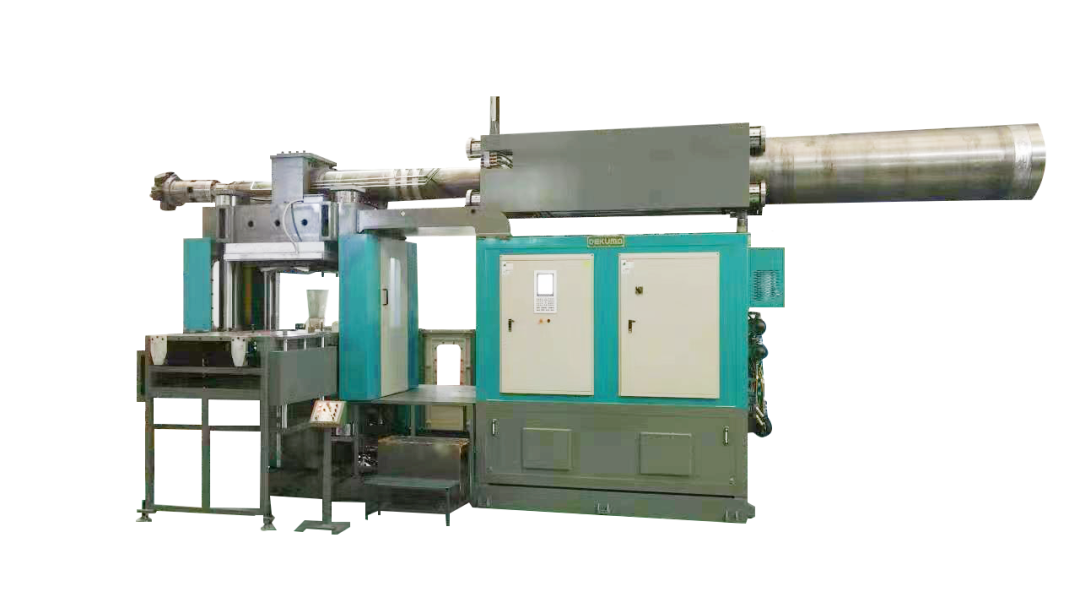

Due to the Pandemic, some colleagues need to work from home, but fortunately, the production has not been affected in our plant. For example, DEKUMA extra-large volume rubber injection molding machine has been successfully completed and released recently.

With this machine, don’t worry about the problem of production efficiency. It is the rubber injection molding machine with the largest injection volume of natural rubber in the country, and can achieve extra-large injection volume of 76000CC in one time. (If you had seen a bigger one, please let me know)

Dekuma DKM-RA1200 extra-large injection volume rubber injection molding machine is specially designed for large and extra-large natural rubber products, which can significantly improve the production efficiency of large natural rubber products such as rubber Mine drum screen, bridge shock absorber and ship anti-collision pad.

Today, the DKM-RA1200 extra-large volume rubber injection machine with a new core technology can achieve larger and faster natural rubber injections, helping customers easily breakthrough the product size limitations and improve production efficiency.

Now let’s take a look at this extra-large volume rubber injection machine~

01 Large plasticizing volume and injection volume

The injection structure designed for natural rubber raw materials can realize ultra-high injection volume of 76L each time, so that customers can produce larger rubber parts than before, expand the production range and improve the production efficiency.

02 Double feeding, double plasticized structure

Double feeding port and double plasticizing structure designed for large injection volume can double the feeding and plasticizing efficiency and significantly improve the production efficiency.

03 Human-machine friendly intelligent operating system

Adopt the most advanced control system in Europe to meet various mold and product process requirements. Large touch screen, with the self-developed operating system by Dekuma, easy to operate.