1, Optimize production processes and increase production capacity.

The highest production speed of this line when producing 14mm microtubes can reach 100m/min.

During the entire line test process, the highest production speed of 7mm microtubes reached the expected goal of 150m/min, and the real-time detection of various product indicators met the requirements of the European customers who visited the site.

2, Automated configuration and efficient winding.

The entire line integrates automated control and is equipped with a dual-position automatic rewinder, greatly improving the degree of automation.

3, Provide a complete set of production solutions to save time and effort.

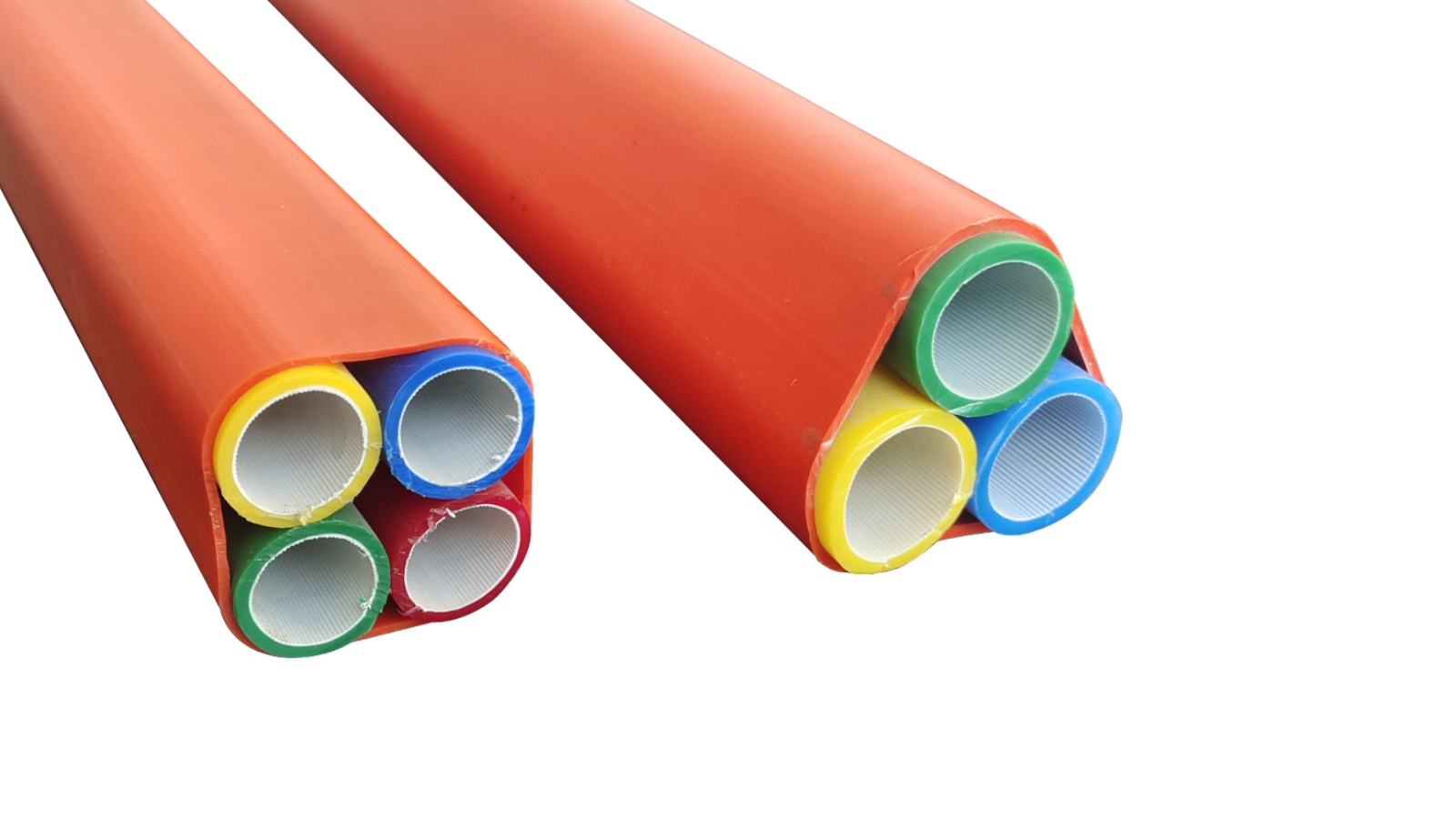

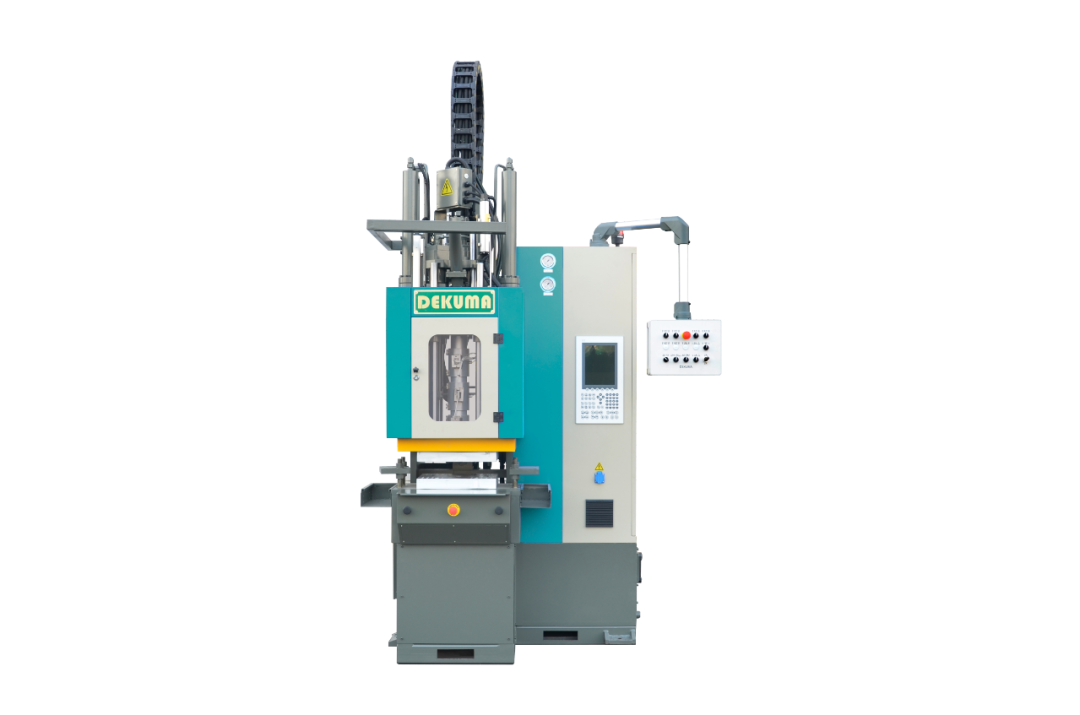

DEKUMA provides users with a complete turnkey solution, with production line plans for all specifications of microducts and various structural bundle tubes.

DEKUMA insists on survival through quality and development through innovation, providing users with better products and services.

The technology of DEKUMA’s microduct production line has reached the leading level in the industry and can meet users’ requirements for high output, high speed, and high efficiency equipment.

At the same time, automated control realizes convenient operation of equipment, reduces dependence on manual labor, and provides a one-stop service for users with a complete set of production solutions, making it the first choice for project investment and equipment upgrades for domestic and foreign customers.

Providing high-quality products and exquisite cutting-edge technology is the primary driving force of innovation at Dekuma.

Providing high-quality products and exquisite cutting-edge technology is the primary driving force of innovation at Dekuma.