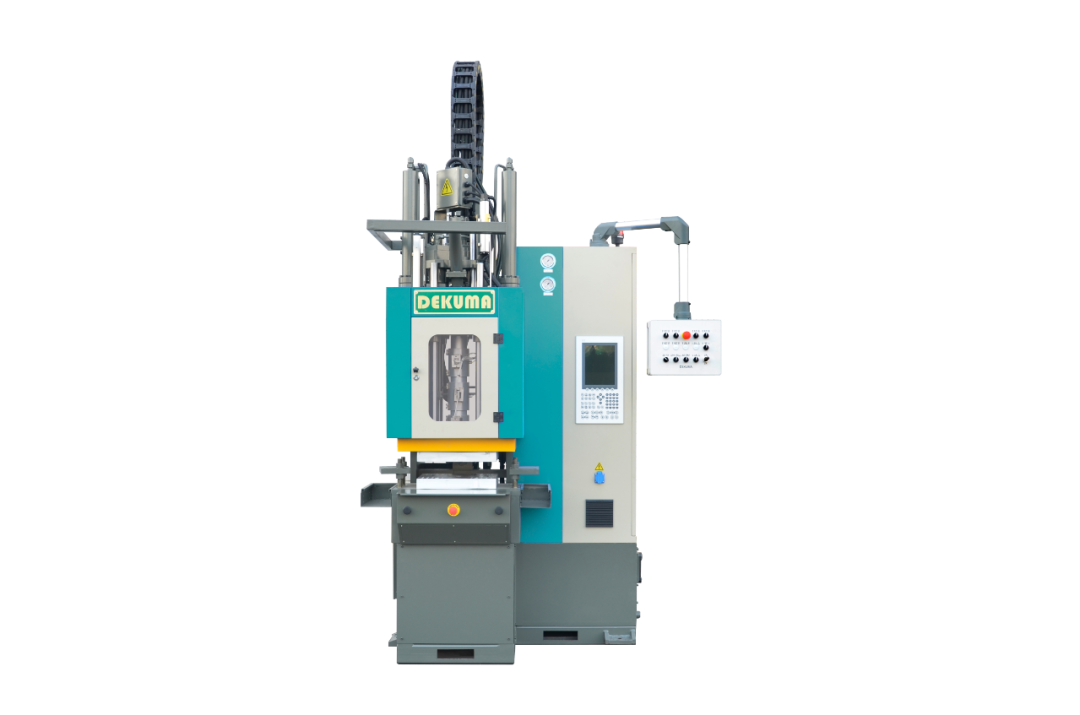

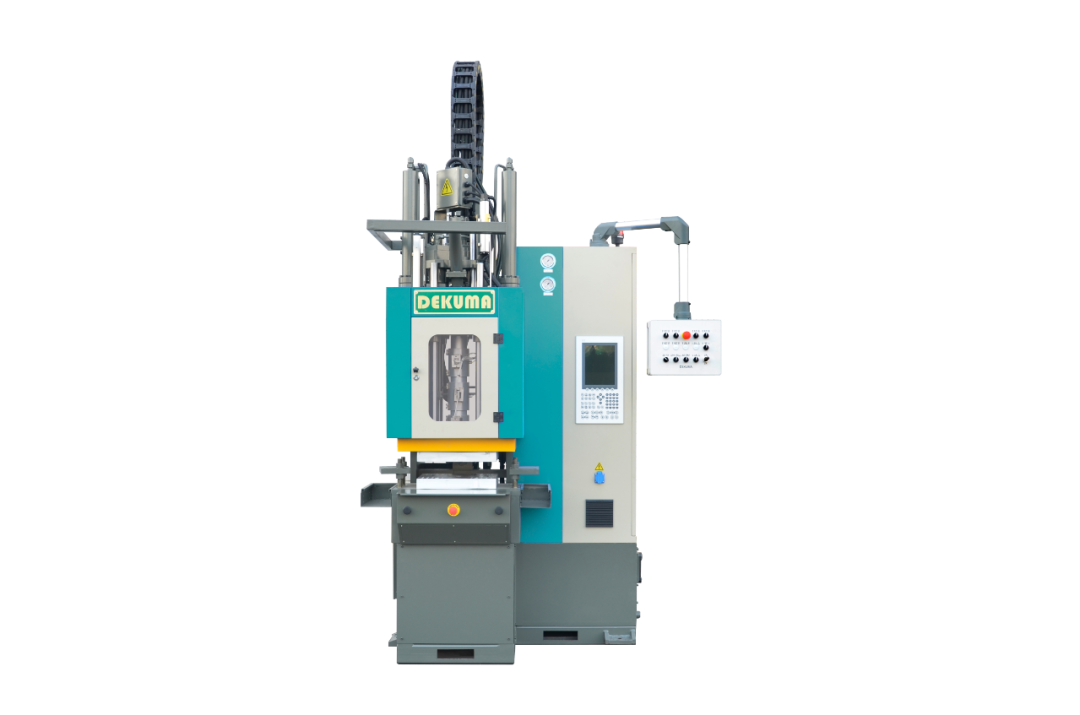

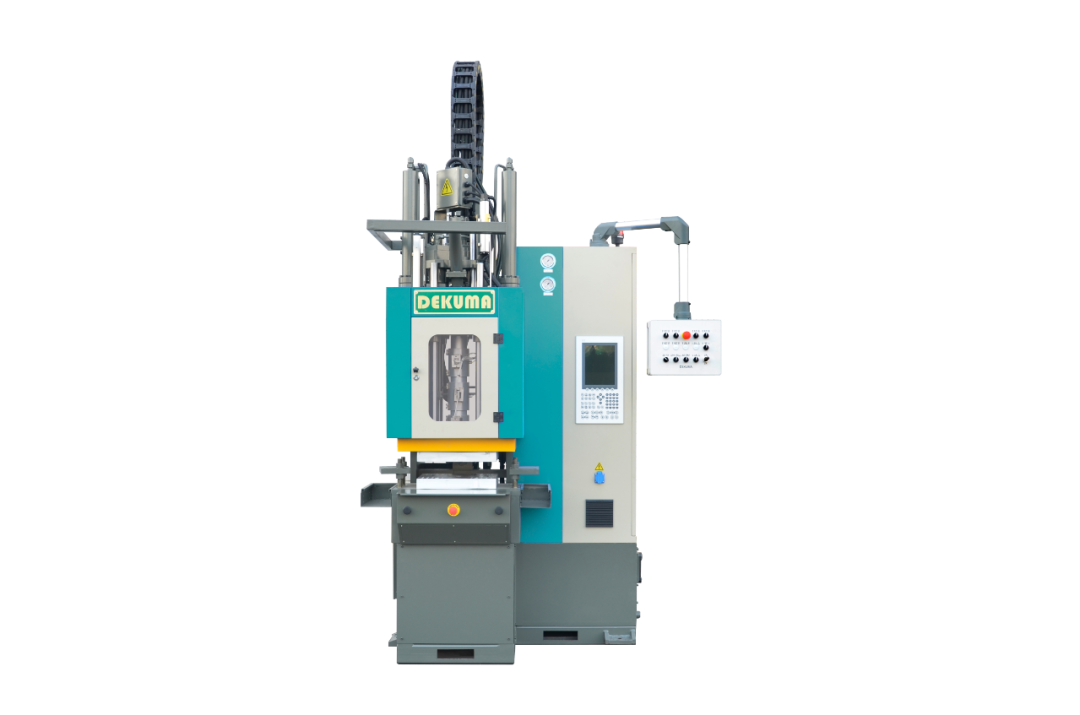

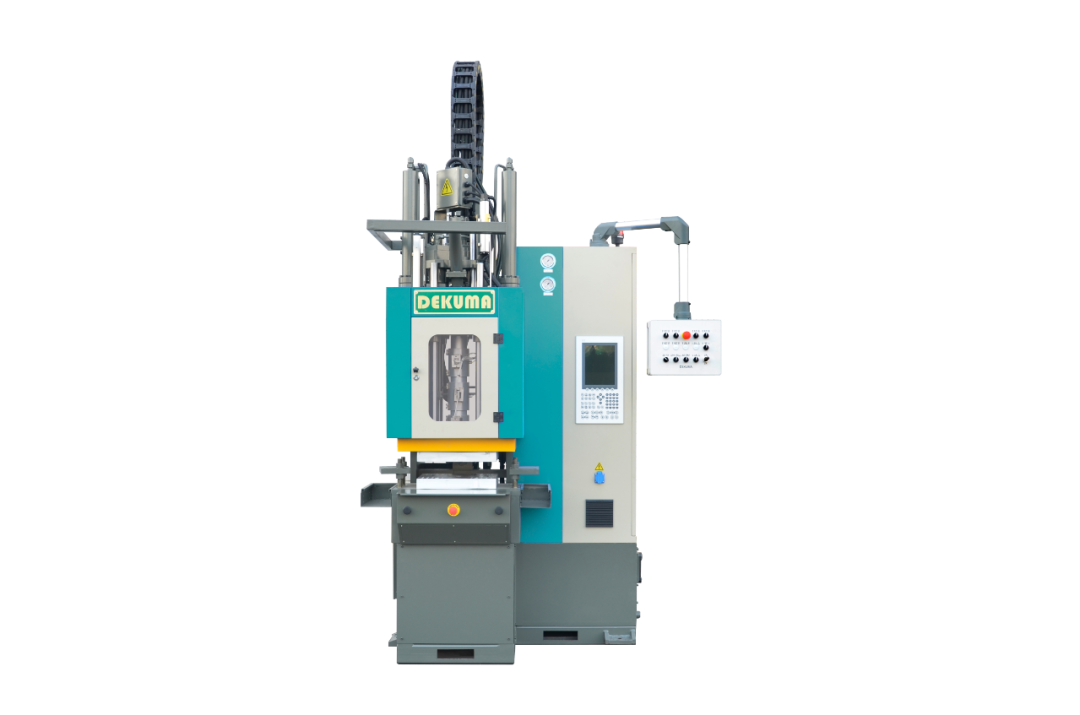

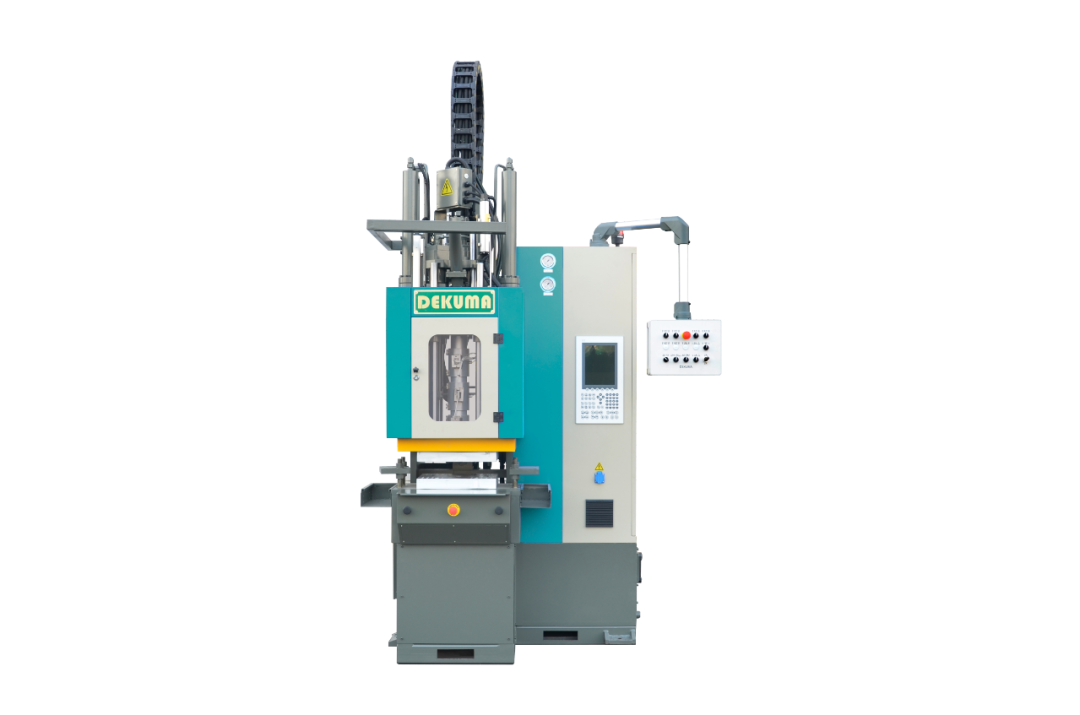

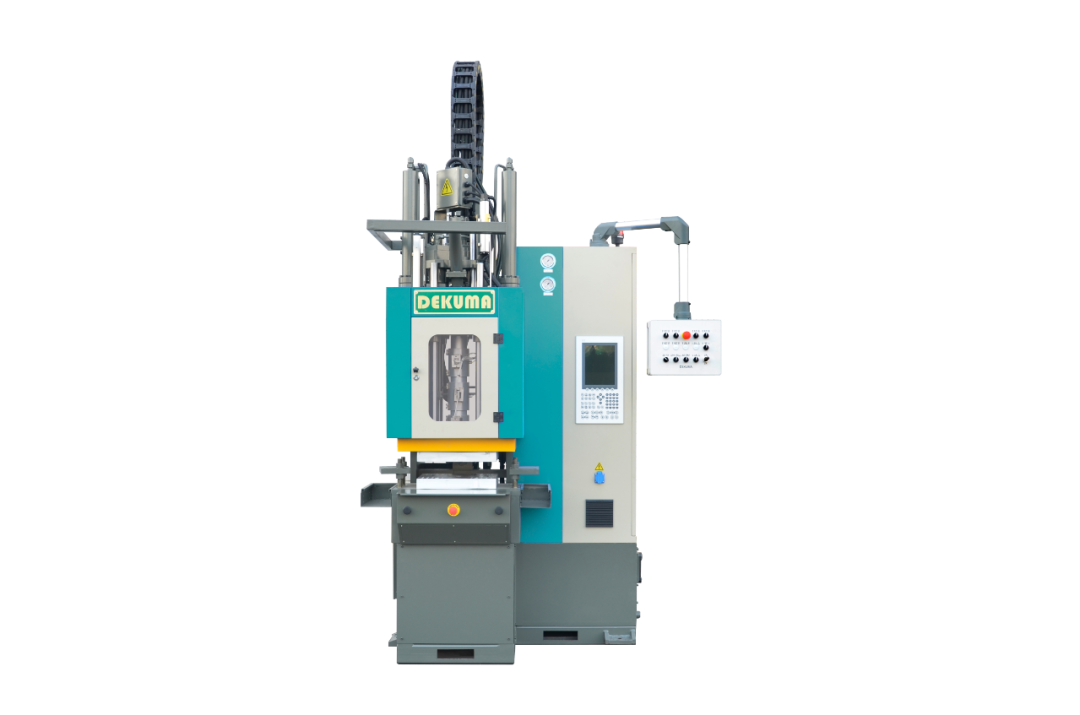

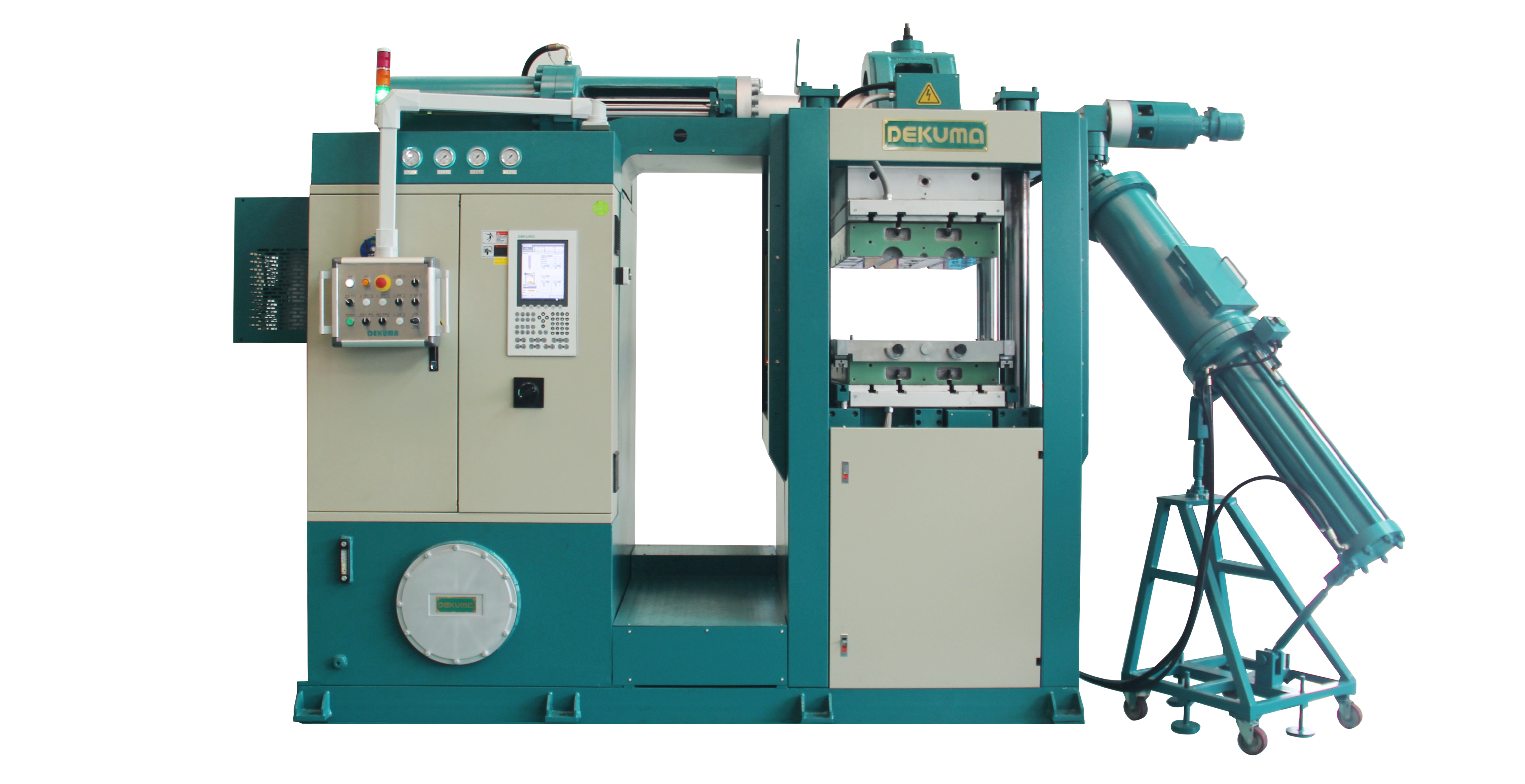

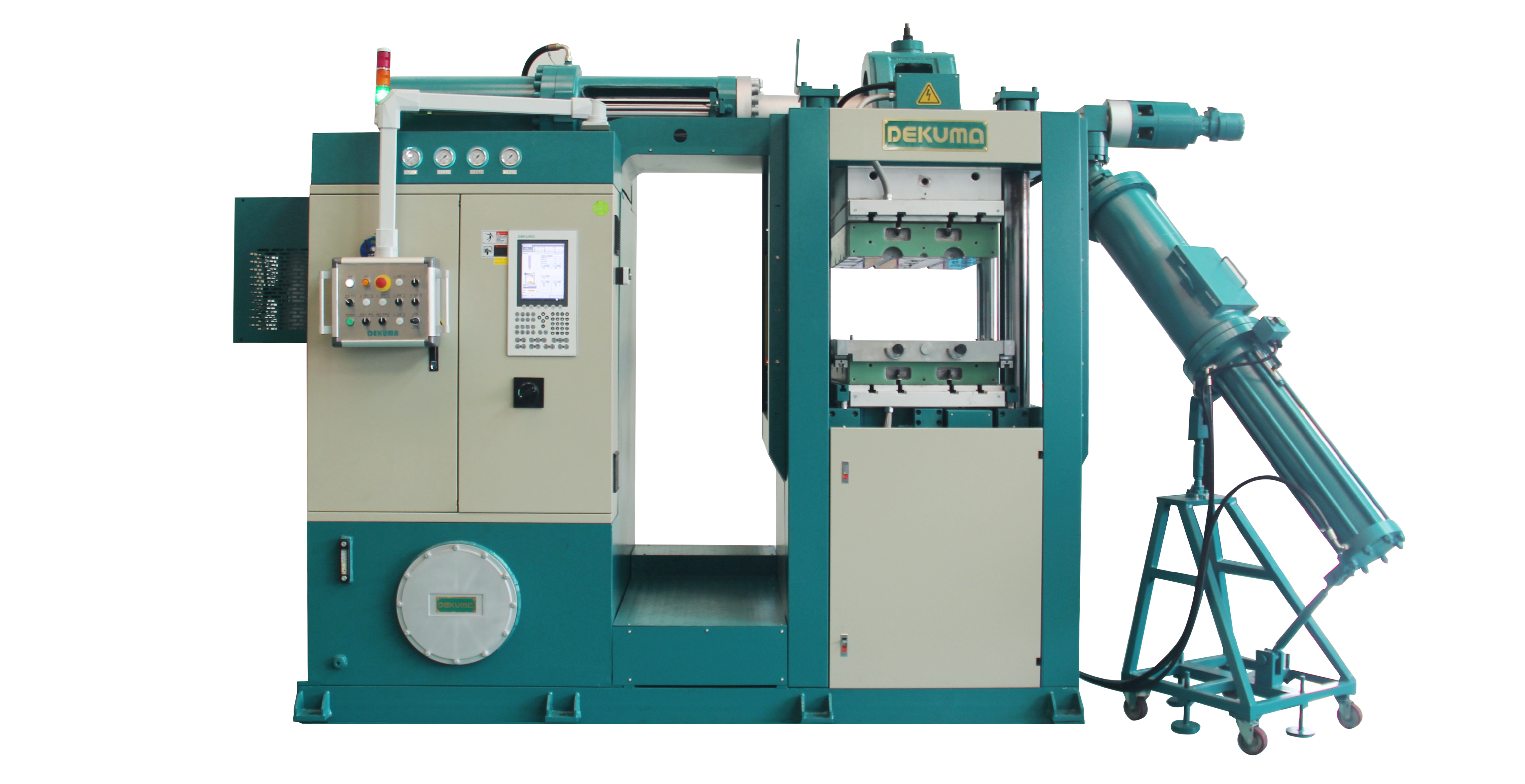

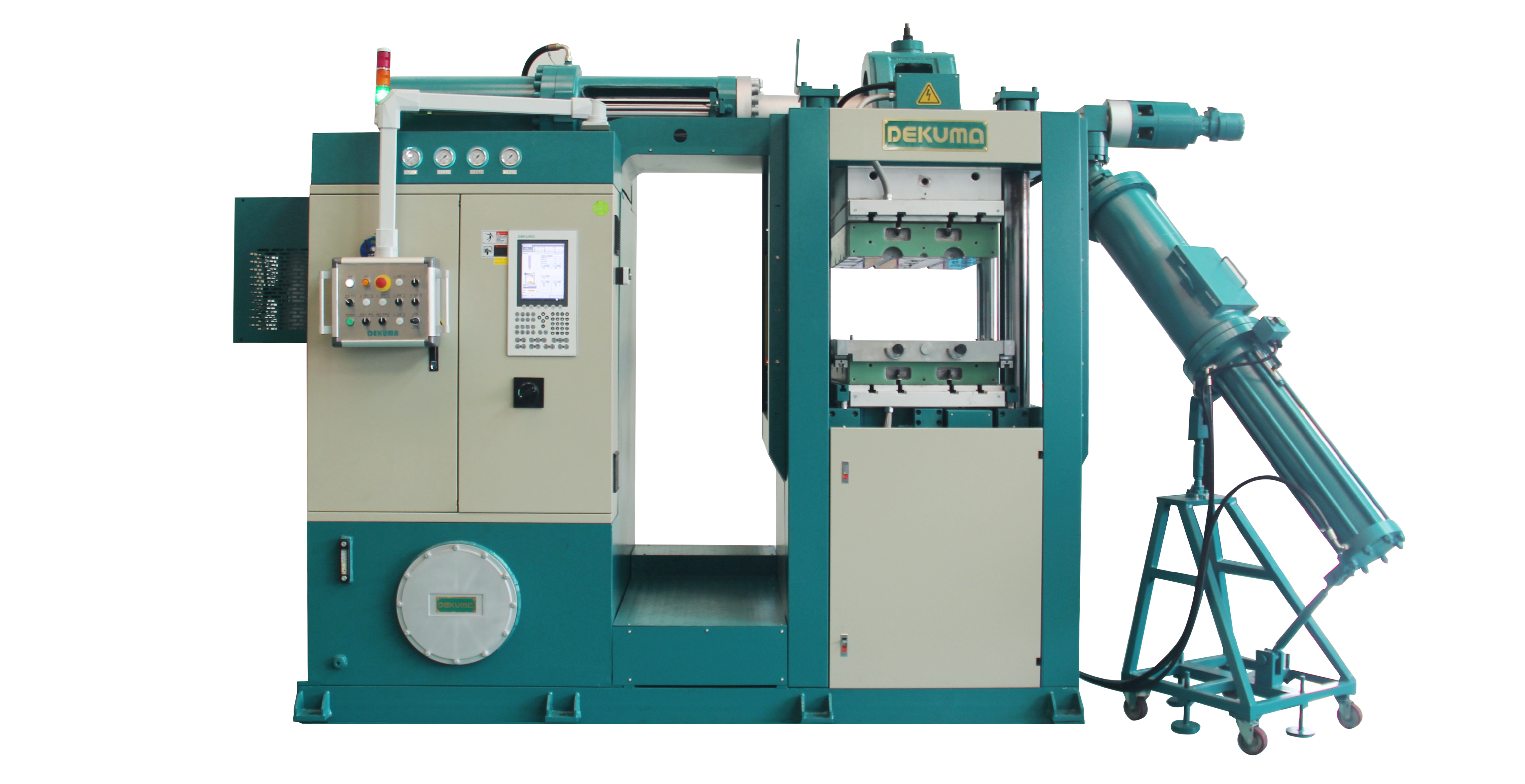

DKM-RV200F Rubber Machine is widely used in the electric power industry, especially in the production of various types of EPDM and silicone rubber cable accessories, such as elbow joints, T-joints, insulating caps, and cable terminal joints.

This equipment has the following features:

1、Flexible structure for easy mold installation

Adopts a direct pressure locking mold structure to facilitate the installation of molds with different thicknesses. In addition, the stepless pull rod structure also ensures sufficient space for mold locking.

2、Safe device to improve production efficiency

The locking mold cylinder comes with a safety pressure protection device to prevent overloading of the locking mold pressure.

3、Anti-loosening structure to extend service life

The pull rod anti-loosening structure ensures that the threads on both ends of the pull rod are secure, evenly stressed, and not easily damaged.

4、Intelligent system for easy operation

Adopts the most advanced control system in Europe to meet the requirements of various molds and product processes.

DKM has always been committed to meeting the needs of users, constantly innovating, and improving product and service quality to provide users with comprehensive solutions.

We believe that the DKM-RV200F Rubber Machine will help users achieve a dual reduction in production costs and management costs, and create more business opportunities and competitive advantages for users.

This product is mainly used for metallic materials such as shallow drawing, press forming and stamping process.

It is suitable for the forming of high-precision parts such as automotive cover parts, interior parts, sealing pads, new energy vehicle battery pack water-cooled plates, computer and server casings, household appliance casings, TV back panels, and plate-type radiators.

1: Newly upgraded with a large table design

3 x 2 meter large bolster, optimized for the pressing of new energy vehicle battery pack water-cooled plates.

2:High precision pressing for improved pressed products pass rate

Ram cylinder slow pressing position repeatability ≤±0.02mm, ram cylinder slow pressing pressure accuracy ≤±1.5bar.

3:Super-strong frame structure designed for reliability and durability

Box type frame structure designed through annealing process, confirm the elastic deformation in maximum pressure through finite element analysis, guiding of moving bolster by eight-face linear guide way, enhance the stability of moving bolster movement and high eccentric pressing force.

4:Fast and flexible to improve production speed

Servo motor drive + two-way cartridge valve control, fast response speed hydraulic system, sensitive action, and reliable operation.

5:Advanced operating system for easy operation

Equipped with a Siemens PLC control system with HMI interface, large touch screen for ease operation.

6:Energy-saving to reduce production costs

Uses a servo motor drive, energy consumption reduced by 30%~50% compare with induction motor.

Drawing on 40 years of hydraulic ingenuity and craftsmanship, Cosmos Press has developed a high-precision frame servo hydraulic press that is a powerful tool for manufacturing precision parts.

Production products of

“RA300 composite insulator rubber machine”▲

Cover a range of different specification of 11KV-66kV insulator.

Large capacity material barrel, easy and convenient for feeding.

DEKUMA has always been in the forefront of niche market dedicated machine, every year will focus on customer needs to launch a new niche market dedicated machine to the market.

Recently, DEKUMA supplied a TPV Knitted Composite Hose Extrusion Line for a Chinese well-known automobile fluid pipeline manufacturer, and completed acceptance successfully.

With the development of electric vehicles (EVs), the advancement of automobile industry technology, and the enhancement of people’s awareness of environmental protection, electric vehicles are becoming more and more popular.

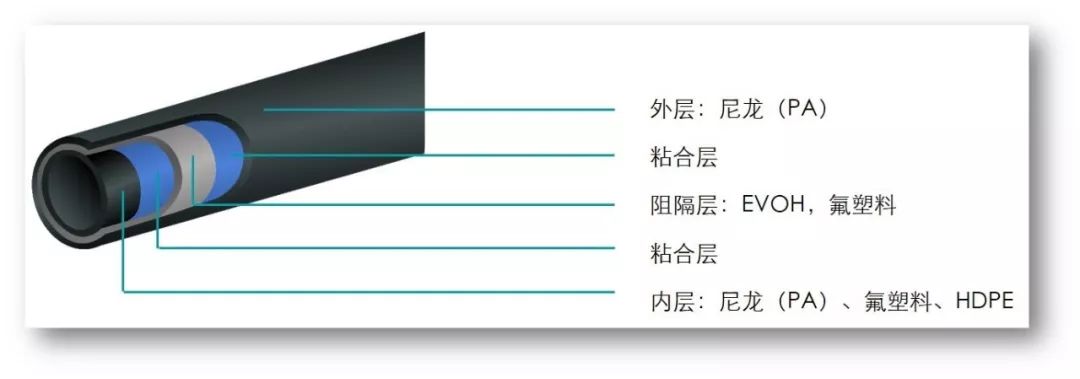

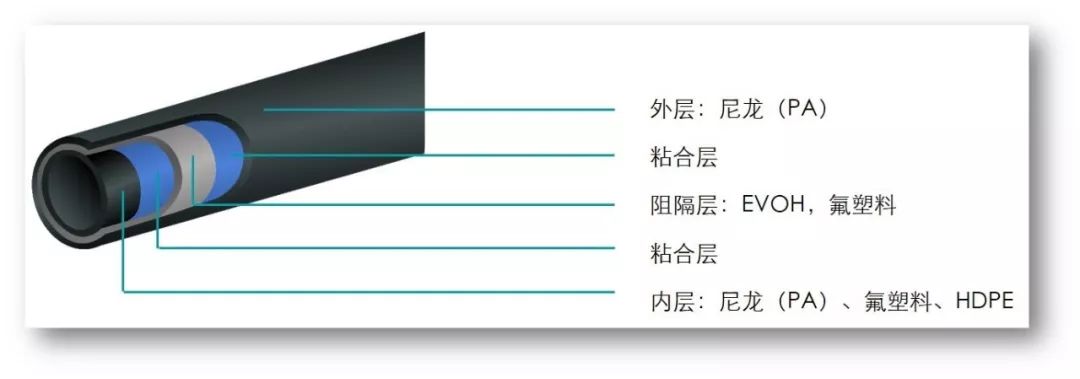

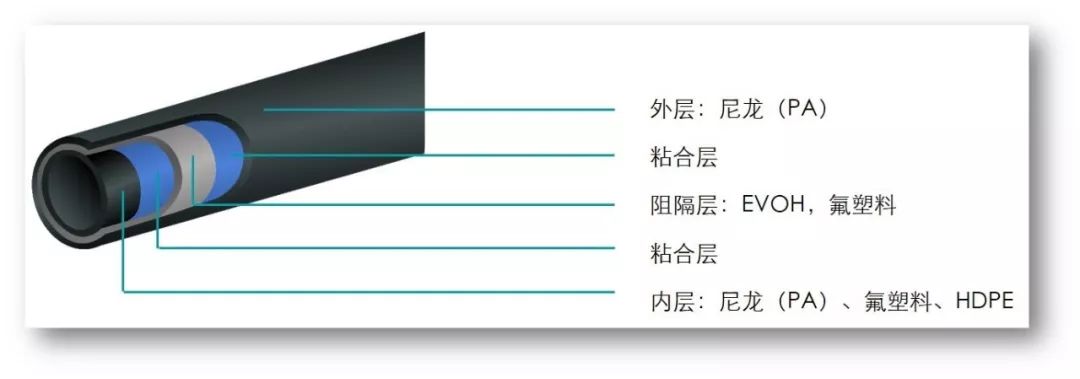

At present, the materials used in the manufacture of automotive fluid pipelines can be divided into three types, metal, rubber, and nylon plastic.

The electric cooling system of EVs is particularly critical, liquid cooling is currently the main way for EVs cooling. As an important part of EVs, coolant fluid pipelines need to meet multiple requirements such as hydrolysis resistance, high temperature resistance, and lightweight.

In recent years, Thermoplastic Vulcanizate (TPV) has the characteristics of both rubber and plastic, and its application in fluid pipelines of EVs has become more and more extensive.

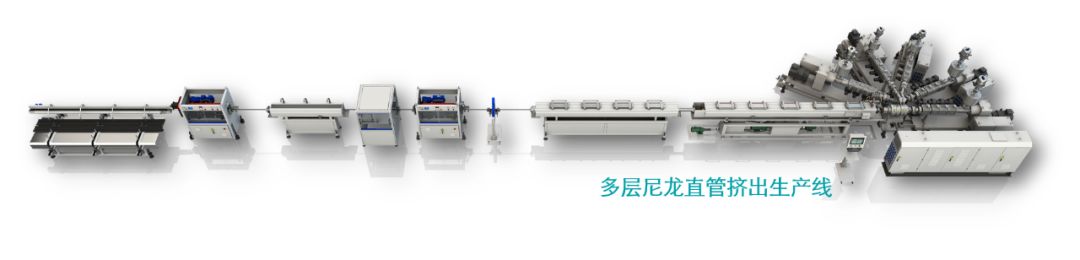

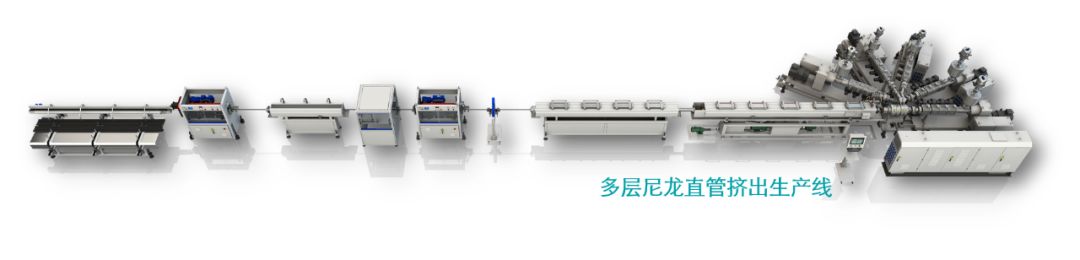

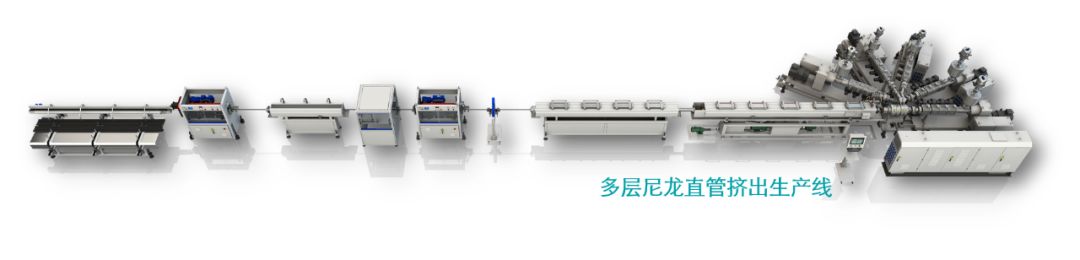

DEKUMA launched TPV Knitted Composite Hose Extrusion Line for EVs, which adopts the combination of TPV (inner layer) + knitted layer (polyester, aramid) + TPV (coating layer), which can simultaneously provide three product structures production solution of TPV knitted composite hose, TPV double-layer composite hose and TPV single-layer hose.

In full use of TPV material light weight, simple process, easy connecting, shockproof characteristics, while using the intermediate fiber knitted reinforcement layer to increase the compressive strength of the hose, improve the safety factor.

TPV can better combine the material characteristics of plastic and rubber, and has alternative advantages in the application of cooling pipeline of EVs in the future.

DEKUMA TPV Knitted Composite Hose Extrusion Line, the inner TPV hose body is accurately extruded by the inner TPV extrusion system, through customized knitted coating fiber reinforced layer, and then through the infrared heating system to make the knitted layer and the inner and outer layer materials perfectly bonded, forming a complete TPV knitted composite hose.

The acceptance samples have been tested and approved by a number of testing institutions in China and Overseas, and the products fully meet the requirements of EVs fluid management.

After nearly three years of development, the application of new materials has gradually extended from “hard” power to “soft” power.

DEKUMA self-developed the TPV Knitted Composite Hose Extrusion Line, which has accelerated the application process of new materials and new fields, and solved the core production problem of “bottleneck” in the development of the auto parts industry.

DEKUMA TPV Knitted Composite Hose Extrusion Line not only realizes the breakthrough in the supply of new materials for EVs, but also further realizes the foresight development of China made equipment, forming a new generation of products and a new line of industry leadership status.

In future, with the increasing application cases of new materials to pipelines, through the continuous exploration of different structure performance, DEKUMA will bring a new boost to the development and iteration of EVs fluid pipeline!