DEKUMA will participate in Middle East Electricity 2023

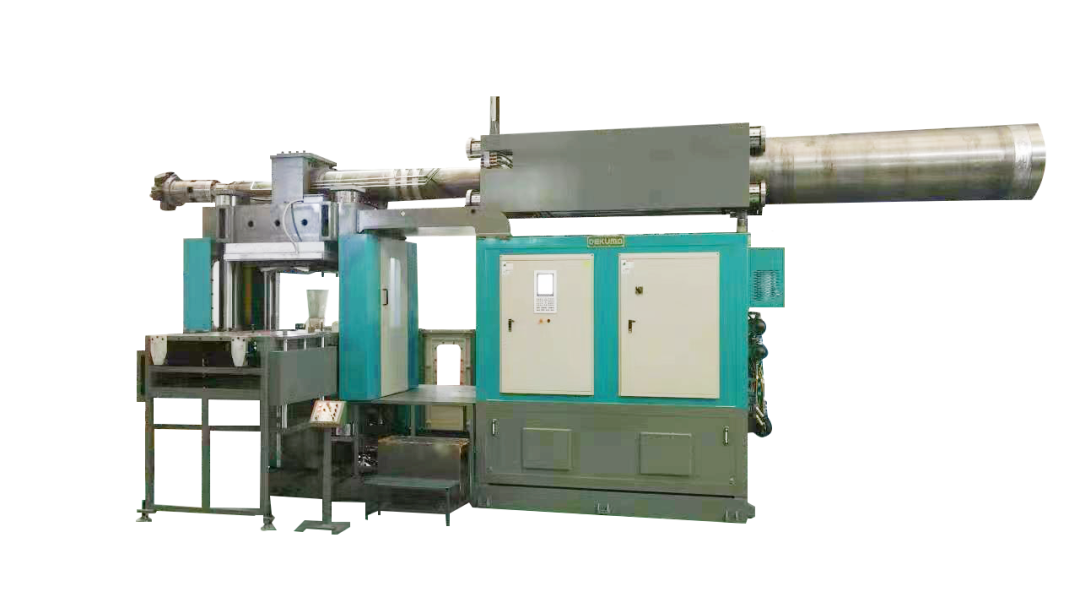

Production products of

“RA300 composite insulator rubber machine”▲

Cover a range of different specification of 11KV-66kV insulator.

Large capacity material barrel, easy and convenient for feeding.

DEKUMA has always been in the forefront of niche market dedicated machine, every year will focus on customer needs to launch a new niche market dedicated machine to the market.

DEKUMA TPV Extrusion Line produces high quality hose for EVs

Recently, DEKUMA supplied a TPV Knitted Composite Hose Extrusion Line for a Chinese well-known automobile fluid pipeline manufacturer, and completed acceptance successfully.

With the development of electric vehicles (EVs), the advancement of automobile industry technology, and the enhancement of people’s awareness of environmental protection, electric vehicles are becoming more and more popular.

At present, the materials used in the manufacture of automotive fluid pipelines can be divided into three types, metal, rubber, and nylon plastic.

The electric cooling system of EVs is particularly critical, liquid cooling is currently the main way for EVs cooling. As an important part of EVs, coolant fluid pipelines need to meet multiple requirements such as hydrolysis resistance, high temperature resistance, and lightweight.

In recent years, Thermoplastic Vulcanizate (TPV) has the characteristics of both rubber and plastic, and its application in fluid pipelines of EVs has become more and more extensive.

DEKUMA launched TPV Knitted Composite Hose Extrusion Line for EVs, which adopts the combination of TPV (inner layer) + knitted layer (polyester, aramid) + TPV (coating layer), which can simultaneously provide three product structures production solution of TPV knitted composite hose, TPV double-layer composite hose and TPV single-layer hose.

In full use of TPV material light weight, simple process, easy connecting, shockproof characteristics, while using the intermediate fiber knitted reinforcement layer to increase the compressive strength of the hose, improve the safety factor.

TPV can better combine the material characteristics of plastic and rubber, and has alternative advantages in the application of cooling pipeline of EVs in the future.

DEKUMA TPV Knitted Composite Hose Extrusion Line, the inner TPV hose body is accurately extruded by the inner TPV extrusion system, through customized knitted coating fiber reinforced layer, and then through the infrared heating system to make the knitted layer and the inner and outer layer materials perfectly bonded, forming a complete TPV knitted composite hose.

The acceptance samples have been tested and approved by a number of testing institutions in China and Overseas, and the products fully meet the requirements of EVs fluid management.

After nearly three years of development, the application of new materials has gradually extended from “hard” power to “soft” power.

DEKUMA self-developed the TPV Knitted Composite Hose Extrusion Line, which has accelerated the application process of new materials and new fields, and solved the core production problem of “bottleneck” in the development of the auto parts industry.

DEKUMA TPV Knitted Composite Hose Extrusion Line not only realizes the breakthrough in the supply of new materials for EVs, but also further realizes the foresight development of China made equipment, forming a new generation of products and a new line of industry leadership status.

In future, with the increasing application cases of new materials to pipelines, through the continuous exploration of different structure performance, DEKUMA will bring a new boost to the development and iteration of EVs fluid pipeline!

Year-end review | Dekuma moves forward in “uncertainty”

Dekuma will continue to provide customers with a complete set of solutions for rubber injection moulding machines, pipe extrusion lines and hydraulic presses based on German technical standards, and continuously improve product reliability and stability.

Dekuma will continue the action of ” both internal and external improvement”. Internally, practice a brand-new corporate culture concept, implement the “five excellence” corporate values, and continue to provide customers with innovative value. Externally, continue to carry out brand marketing and promotion, and expand and strengthen the brand influence of Dekuma.

Dekuma will work hard and forge ahead, with the mission of “technology assists the development of the rubber and plastic industry, innovation promotes the upgrading of Chinese manufacturing”, and uses technological innovation and ingenuity to help manufacturing enterprises to a new level.

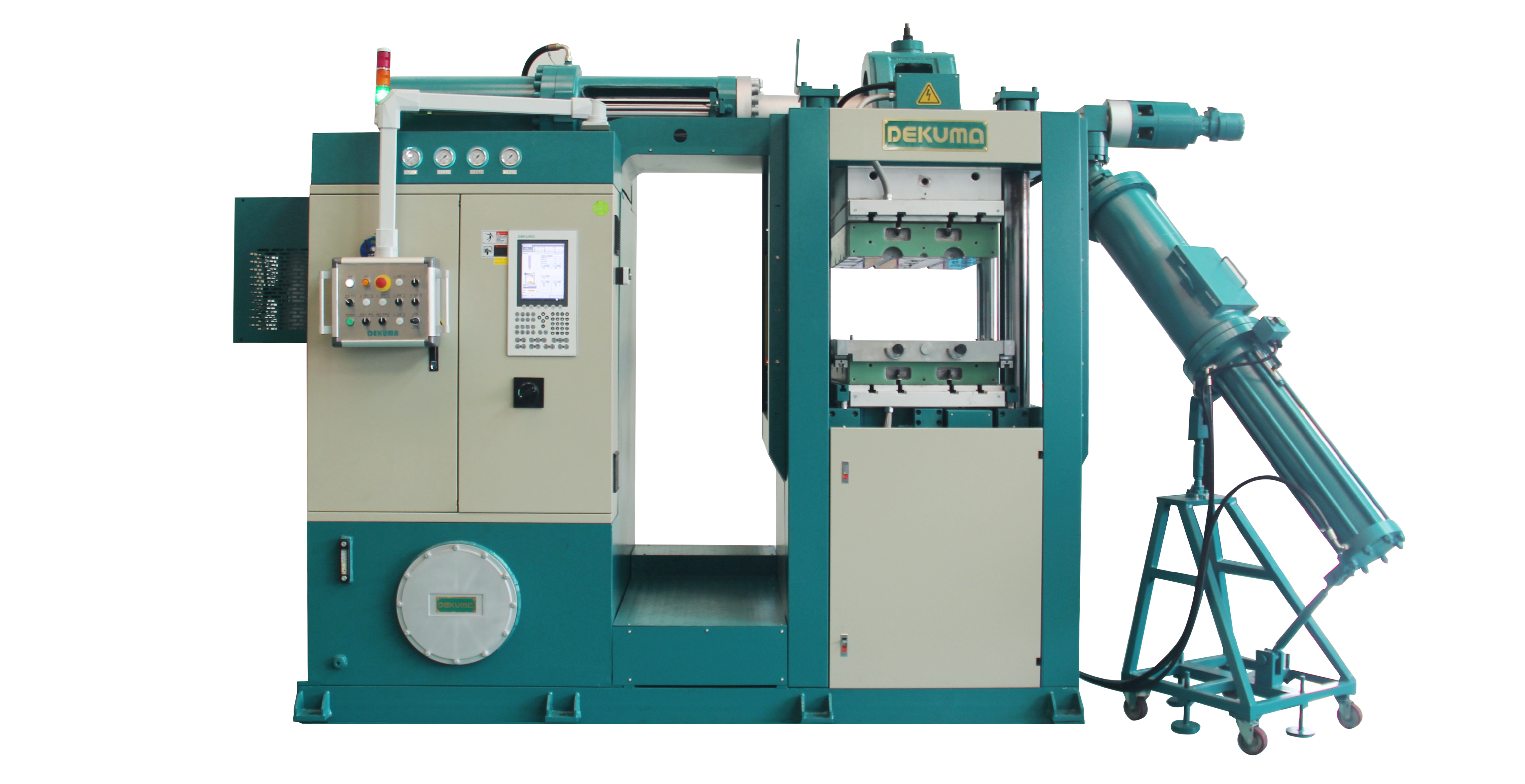

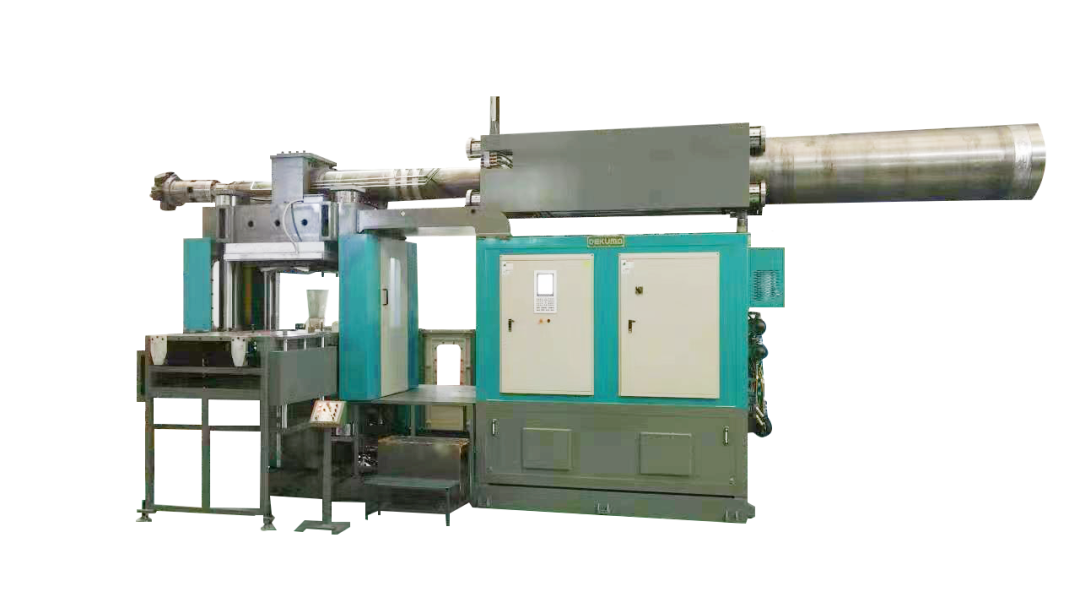

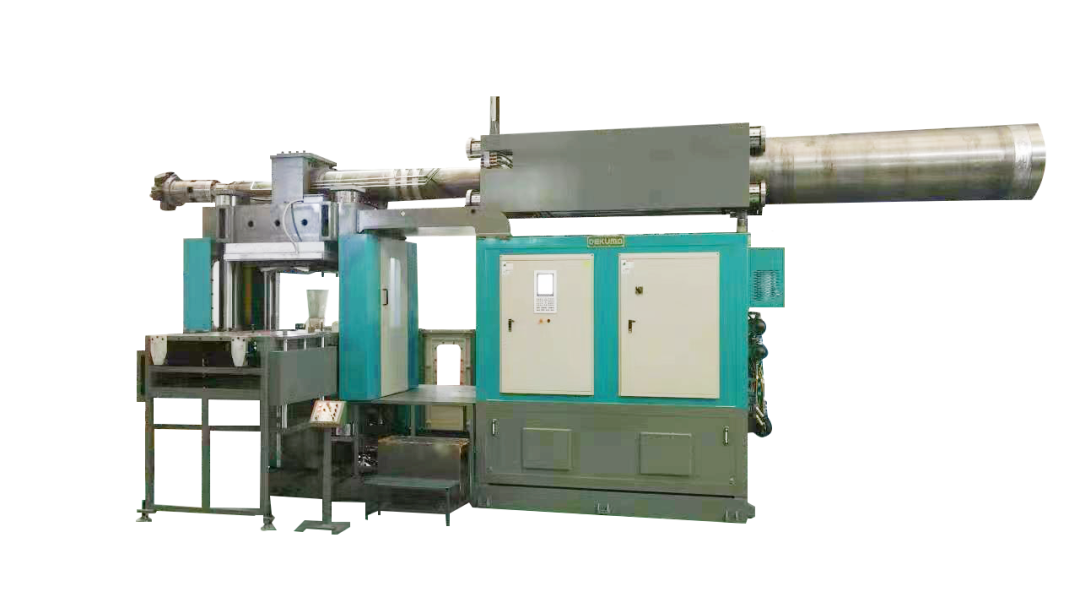

Natural rubber achieving incredible injection volume of 76000cc!

Due to the Pandemic, some colleagues need to work from home, but fortunately, the production has not been affected in our plant. For example, DEKUMA extra-large volume rubber injection molding machine has been successfully completed and released recently.

With this machine, don’t worry about the problem of production efficiency. It is the rubber injection molding machine with the largest injection volume of natural rubber in the country, and can achieve extra-large injection volume of 76000CC in one time. (If you had seen a bigger one, please let me know)

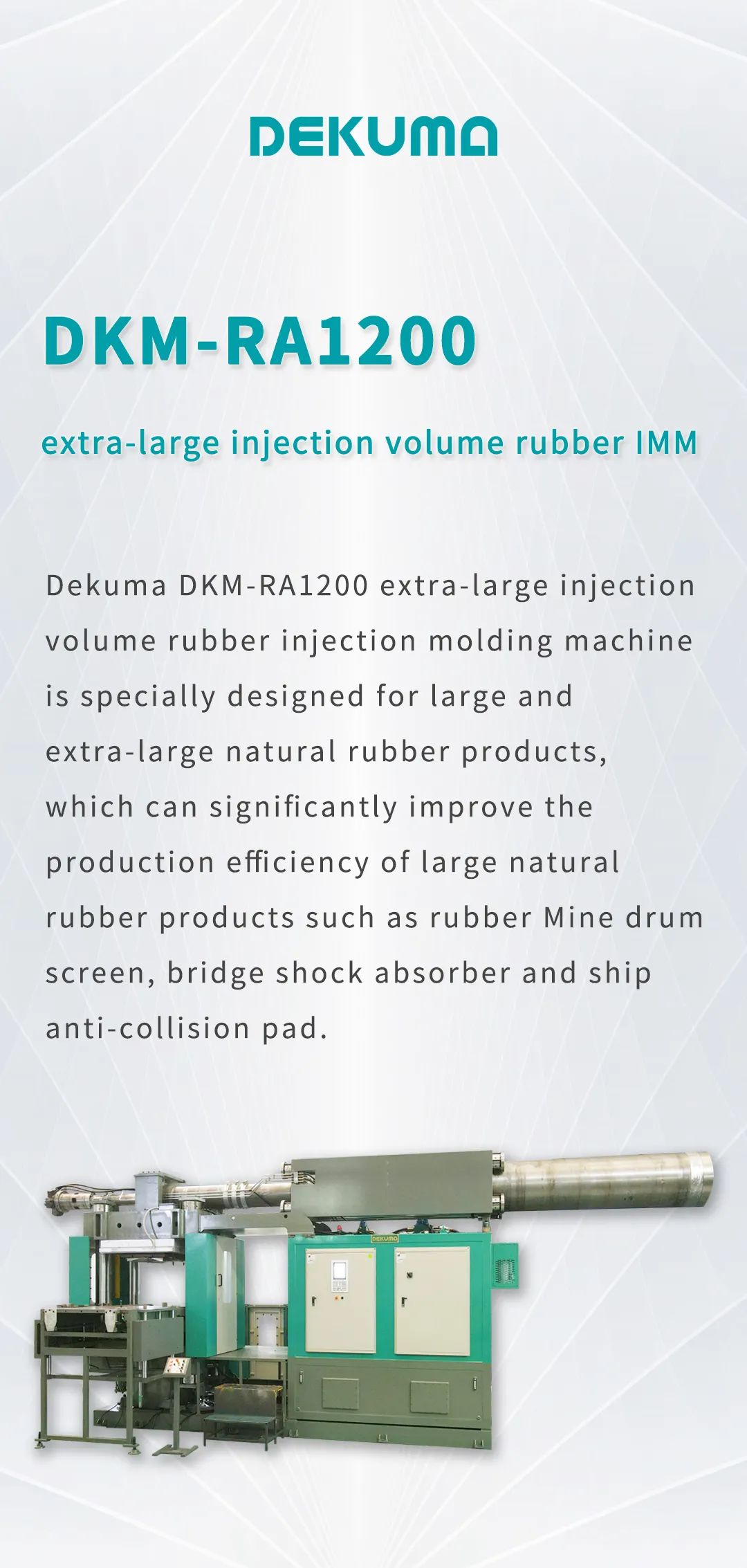

Dekuma DKM-RA1200 extra-large injection volume rubber injection molding machine is specially designed for large and extra-large natural rubber products, which can significantly improve the production efficiency of large natural rubber products such as rubber Mine drum screen, bridge shock absorber and ship anti-collision pad.

Today, the DKM-RA1200 extra-large volume rubber injection machine with a new core technology can achieve larger and faster natural rubber injections, helping customers easily breakthrough the product size limitations and improve production efficiency.

Now let’s take a look at this extra-large volume rubber injection machine~

01 Large plasticizing volume and injection volume

The injection structure designed for natural rubber raw materials can realize ultra-high injection volume of 76L each time, so that customers can produce larger rubber parts than before, expand the production range and improve the production efficiency.

02 Double feeding, double plasticized structure

Double feeding port and double plasticizing structure designed for large injection volume can double the feeding and plasticizing efficiency and significantly improve the production efficiency.

03 Human-machine friendly intelligent operating system

Adopt the most advanced control system in Europe to meet various mold and product process requirements. Large touch screen, with the self-developed operating system by Dekuma, easy to operate.

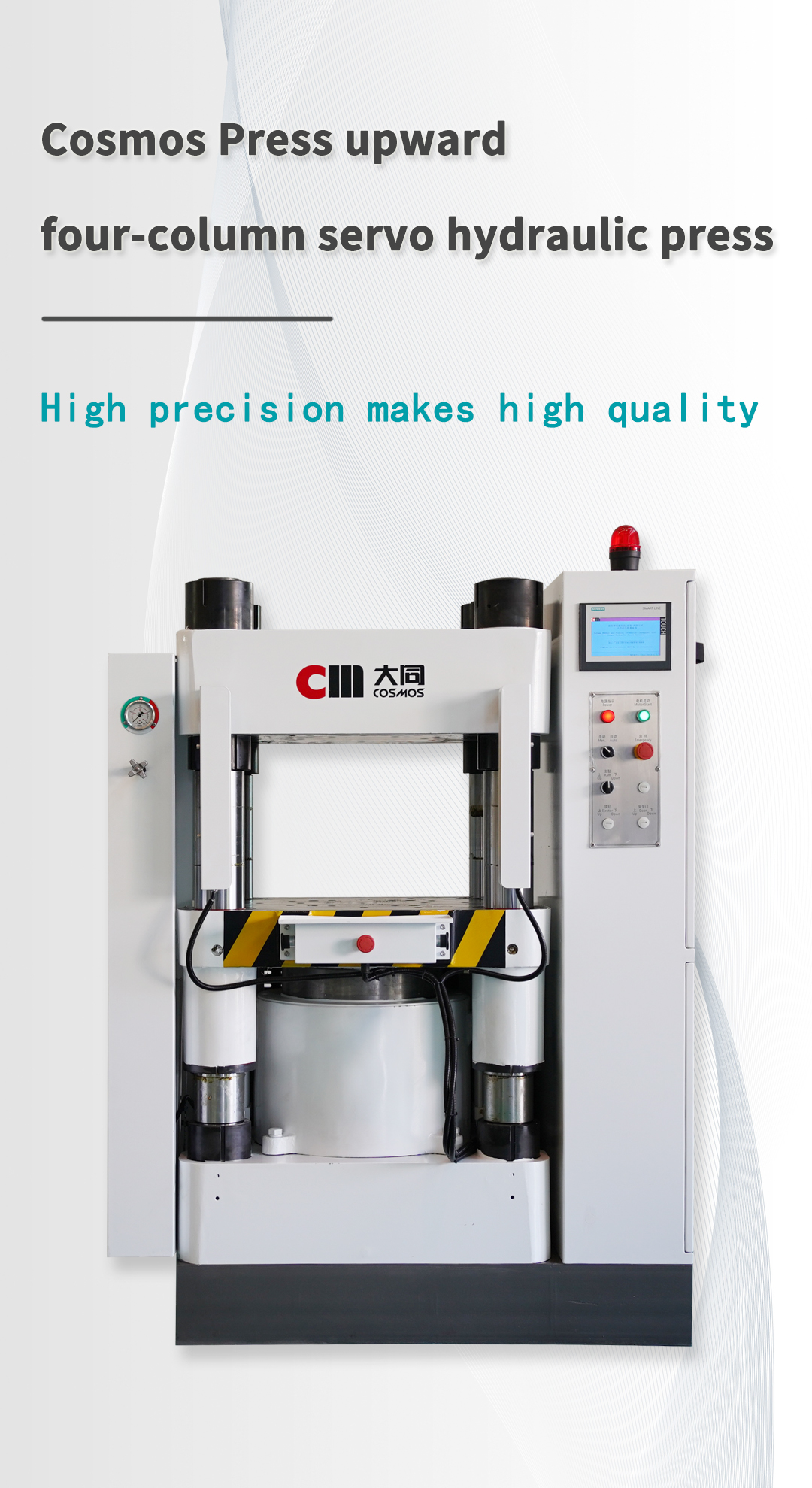

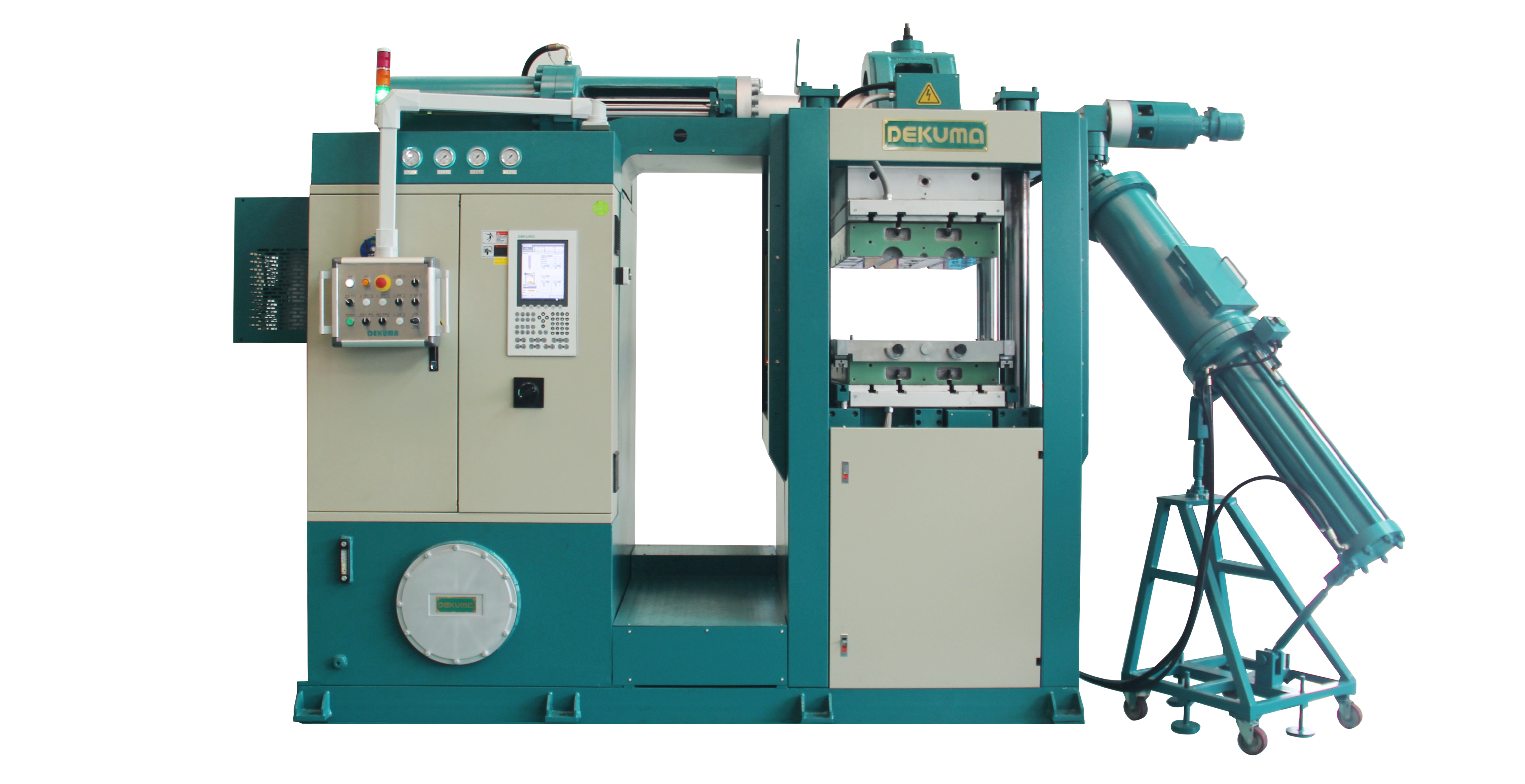

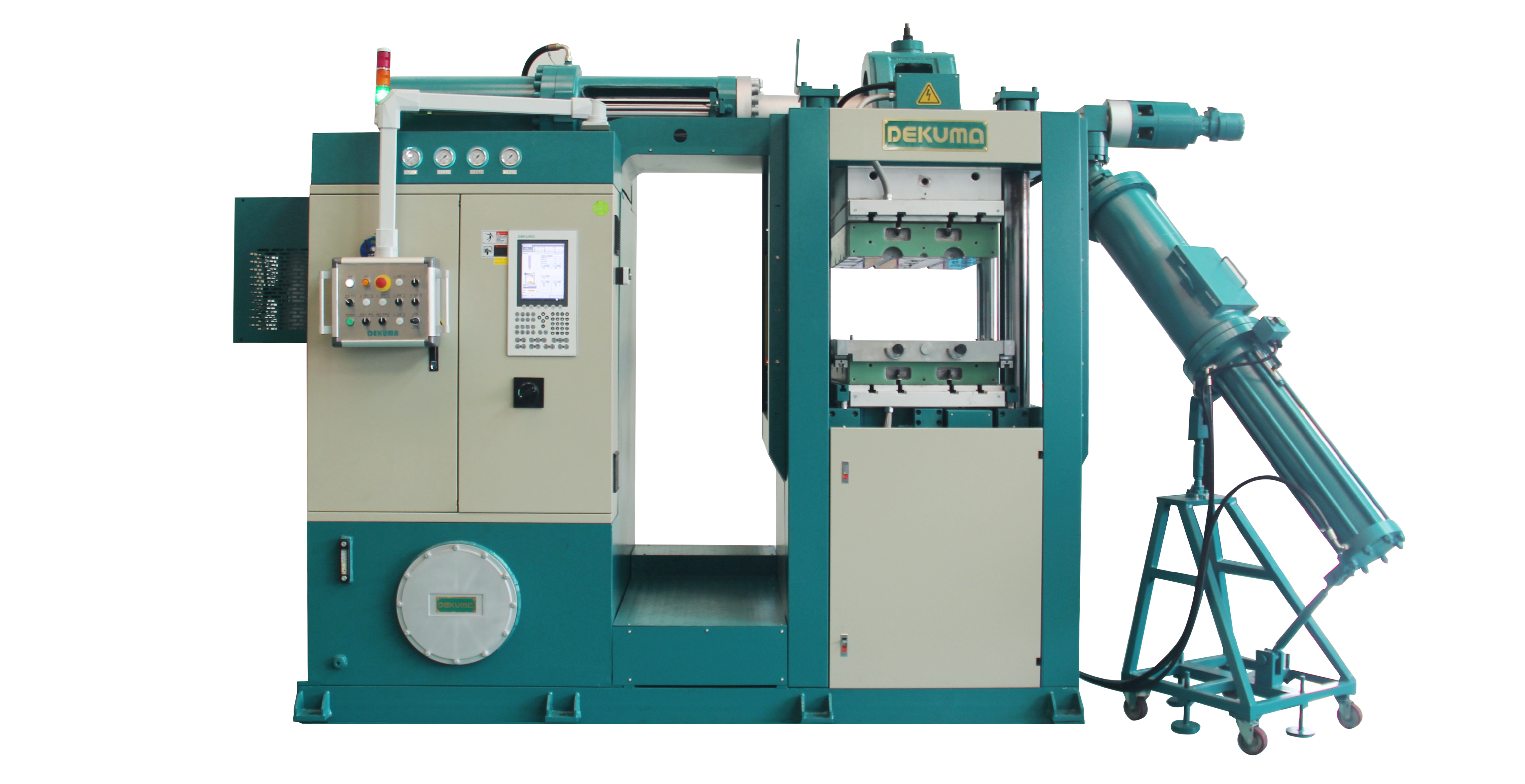

20-year co-operation between Cosmos Press and high-end customers

01 Ultra-high precision, improve product quality

Main cylinder slow press repeat pressure accuracy: ±1.5bar, master cylinder slow press repeat position accuracy: ±0.01mm, even if an upright coin is placed, it will not fall down. Ultra-high pressure accuracy and position accuracy can significantly improve product qualification rate and reduce damage to molds.

02 Servo drive, energy saving and environmental friendly

According to the actual needs of each process, there is no loss in the output torque speed, thereby reducing impact noise. Compared with conventional hydraulic presses, it can save energy by about 30%-50%.

03 Precise guiding, prolonging the service life of the mould

The guide length of the moving beam is more than twice the stroke of the main cylinder, and the precise guide can improve the protection of the mould.

High precision machine produces high quality product. For more than 20 years, high-end customers have been using Cosmos up stroke four-column servo driven hydraulic press. It has many advantages.

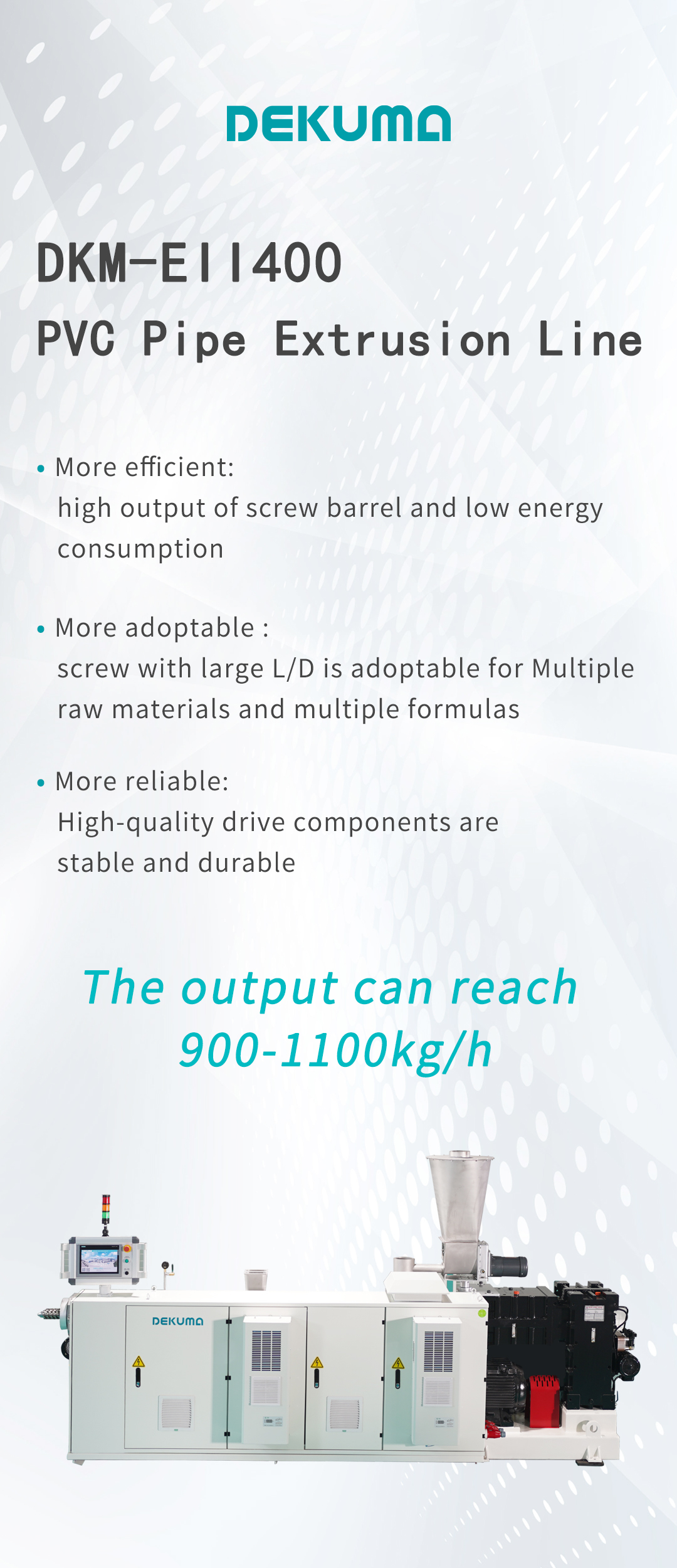

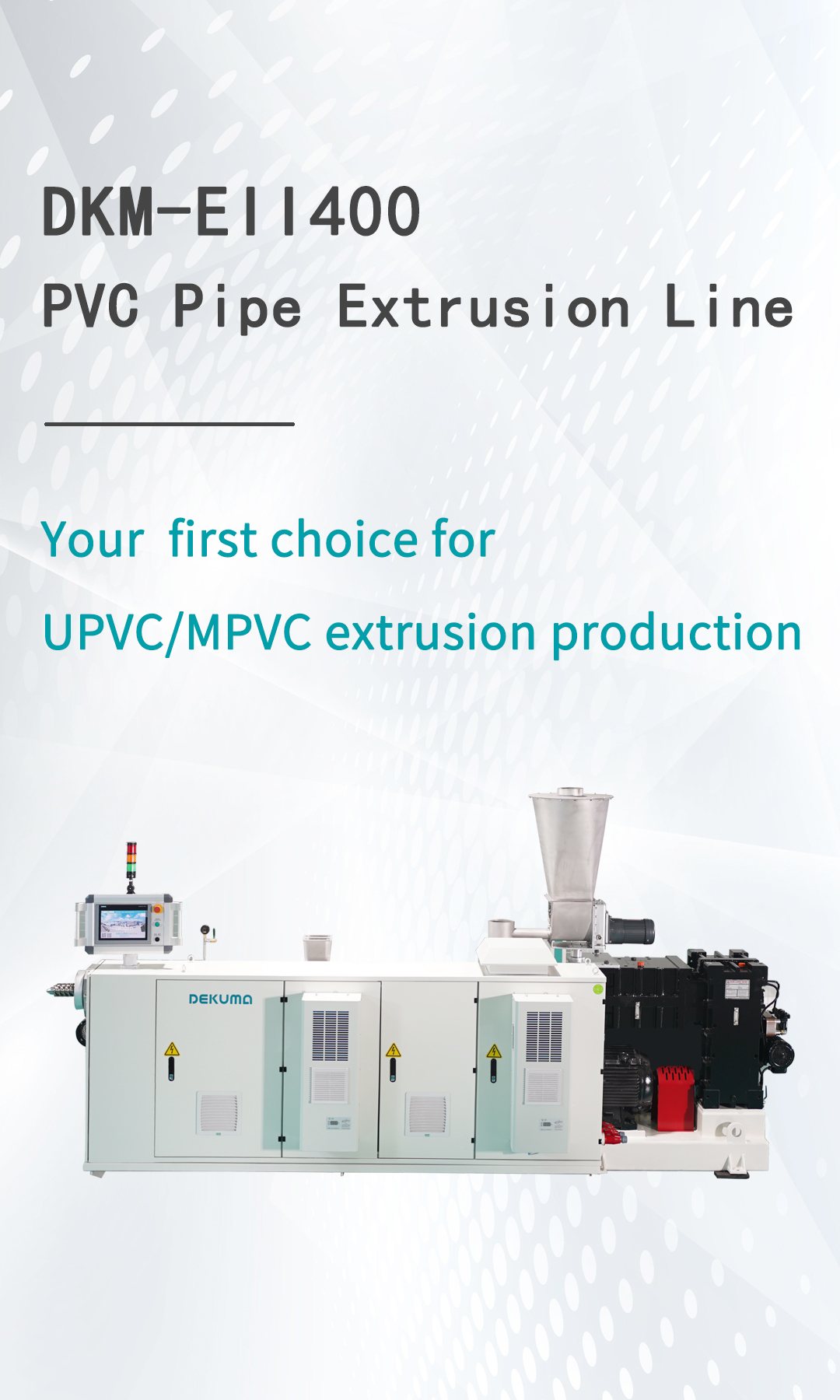

The Tips of DEKUMA 400PVC Pipe Extrusion Line

最近德库玛销售很忙,和客户沟通安装细节,因为一条新的400mm PVC管材挤出生产线正在运往巴西。

是个大家伙,最大产量可达900-1100kg/h。它有三个“更多” 。

更高效:螺杆机筒产量高,能耗低。

适应性强:大长径螺杆适用于多种原料、多种配方。

更可靠:优质驱动部件,稳定耐用。

它所有的巨大优势!

我们已经与巴西客户合作了 5 年。我们一直赢得他们的信任和好评。

主要原因是我们Dekuma具有真诚、敬业、客户至上的服务精神。

即使无法亲临现场,我们也会通过完整全面的手册,远程协助客户顺利完成安装调试。

保持快速负责的服务,高效可靠的设备。这些是与客户保持长期合作的秘诀。

那么这款机器有哪些优势呢?让我们来看看。

01 高效省材

DEKUMA 400PVC管材挤出生产线可适应uPVC、mPVC低钙多配方,开机成本远低于同行。

02 产量更高,能耗更低

配备DKM-EII138x28A平行双螺杆挤出机,稳定挤出产量可达900-1100kg/h。

低能耗也是这款挤出机的重要亮点,使其始终走在同类机型的前列。

03 可靠实用

意大利进口品牌齿轮箱,强大的动力传动系统,在更小中心距的情况下搭配更大直径的螺杆,最大限度地提高平行双螺杆挤出机的挤出效率,具有长期的可靠性和实用性。

04 耐用的螺杆和机筒

螺杆机筒采用优质材料,锻造件,严格按照标准生产工艺进行调质处理,具有良好的机械稳定性和表面质量。

保证物料顺利通过流道挤出,保证管材优良的力学性能和表面质量。

05 整线配置合理

下游真空定型罐、冷却罐、牵引机、切割机等均按照德科玛统一的质量标准设计、加工、制造。整线稳定高效。

DEKUMA PVC挤出生产线已远销中东、非洲、南美等国家和地区,性能得到充分验证。

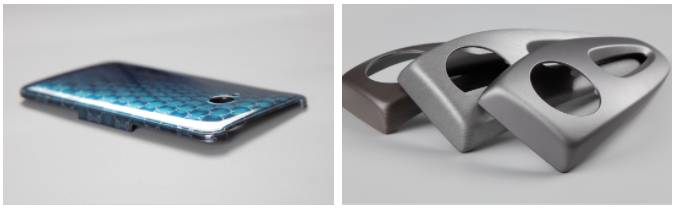

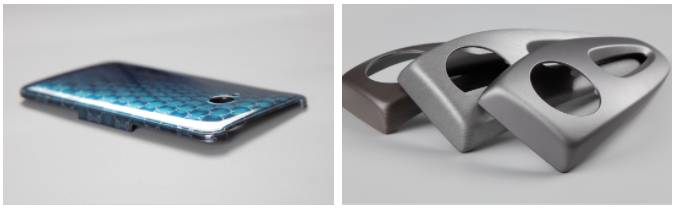

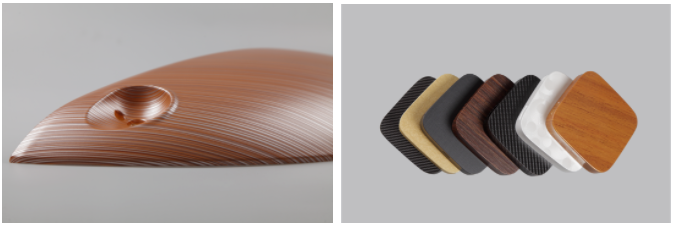

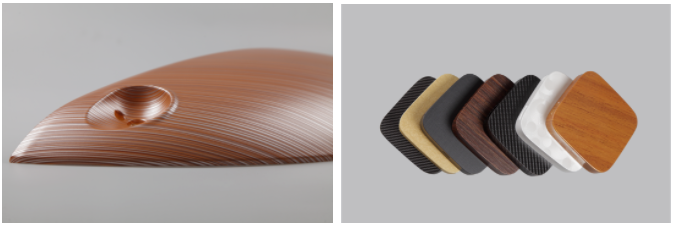

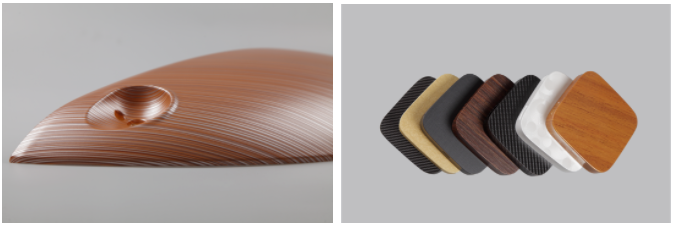

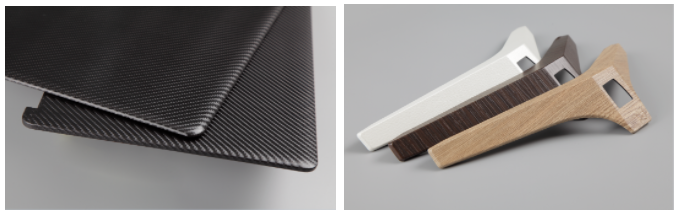

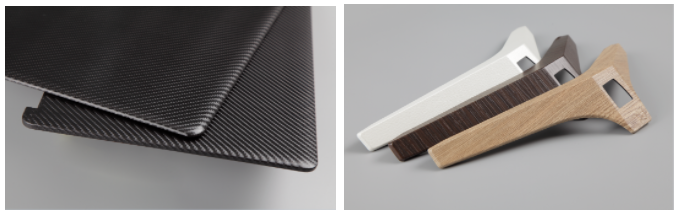

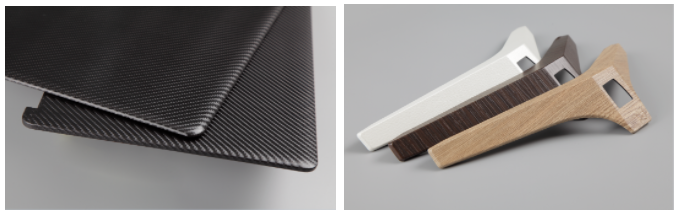

Decryption of DEKUMA’s “Outside Mold Decoration Technology”

With the continuous development,OMD technology has been deeply concerned and sought after by various industries for its unique product appearance decoration effect .

To fill the domestic technical vacancy and continuously achieve breakthroughs in the new technical field, DEKUMA has launched a new DOD (differential pressure overlay decoration) technology scheme through independent research and development and years of project practice, which s Solve the problem of China’s dependence on imported equipment and imported film materials, with the aim to provide customers with complete equipment-film-production solutions, so as to realize the localization.

01 Introduction of OMD process

DOD (Differential Pressure Overlay Decoration) is a new technology scheme of OMD (Out Mold Decoration) lauched by DEKUMA as well as an extension of IMD (In-Mold Decoration).

OMD uses heating, vacuum and high-pressure gas to realize product surface overlaying or transfer printing, and can realize 3D surface decoration process with higher quality appearance effect, and belongs to three-dimensional appearance decoration technology.

As an extension of IMD process, it combines texture effects such as color and texture, and perfectly combines printing technology, texture and metallization characteristics, so that it can make more three-dimensional and highly 3D curved surface products and achieve many appearance effects, including metal wire drawing, wood grain, stone grain, leather and etc.

02 Process characteristics of OMD

OMD process can be used to decorate the surfaces of various materials: plastic, glass, metal, wood, stone, etc., because the softening temperature of the film in the manufacturing process is lower than that of the in-mold decoration, and then the touch will be better preserved, and it will not be easily weakened or disappear. The touch has obvious concave-convex feeling, which can solve the overlaying problem and yield of complex products that cannot be handled by manpower.

03 Introduction of OMD process flow

OMD equipment process is a process where the vacuum and atmospheric pressure are used to make the film with adhesive layer heated and overlaid on the surface of the product and tightly attached.

The key point of manufacturing lies in the utilization of pressure difference. Through locating, evacuating, film heating, pressurizing and other operations, the mold can be opened and the product can be taken out after six steps.

04 Advantages of OMD process

05 Development of DEKUMA in OMD process