In recent years, dekomo——Cosmos Press focuses on the research and development of special hydraulic press for automobile Braking plates. It has the characteristics of high repetition positioning accuracy, low noise, energy saving and environmental protection, simple operation and maintenance, and is widely recognized by customers.

Improved 300 ton Braking plate hydraulic press

Original 300 ton Braking plate hydraulic press

Recently, delcomo has improved the original 300 tonBraking plates hydraulic press by moving the oil tank up. The improved hydraulic press covers a smaller area and can be installed with manipulators all around, which makes the operation more convenient and flexible, and effectively improves the utilization rate of customers for the site.

This type of hydraulic press can produce 16-18 Braking plates steel backs per minute in the production of manipulator; under the condition of manual operation, it can produce more than 20 pieces per minute, fully meeting the needs of customers for providing production efficiency.

Braking plate steel back

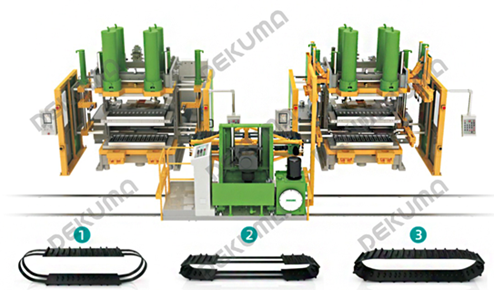

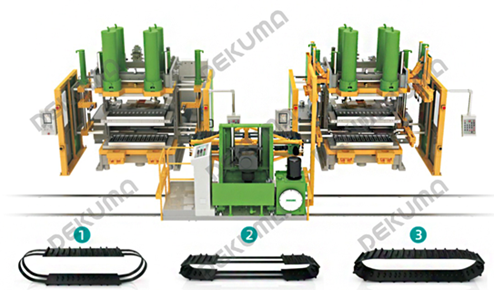

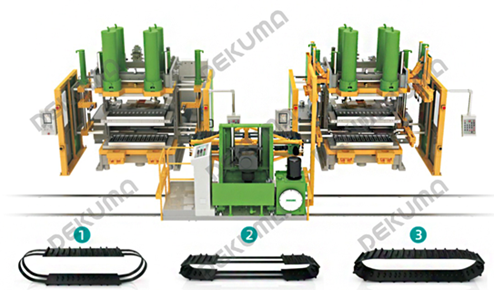

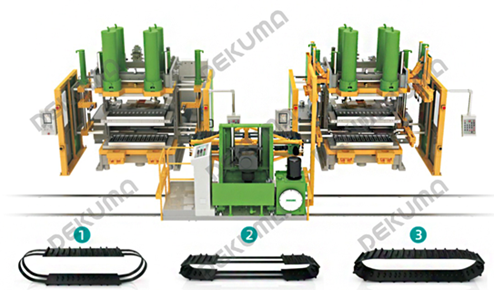

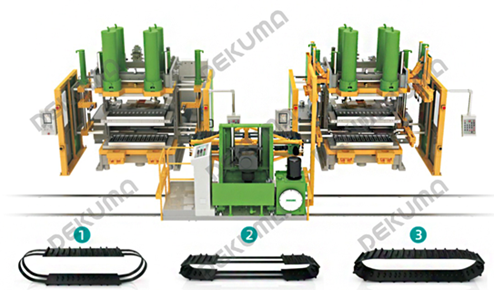

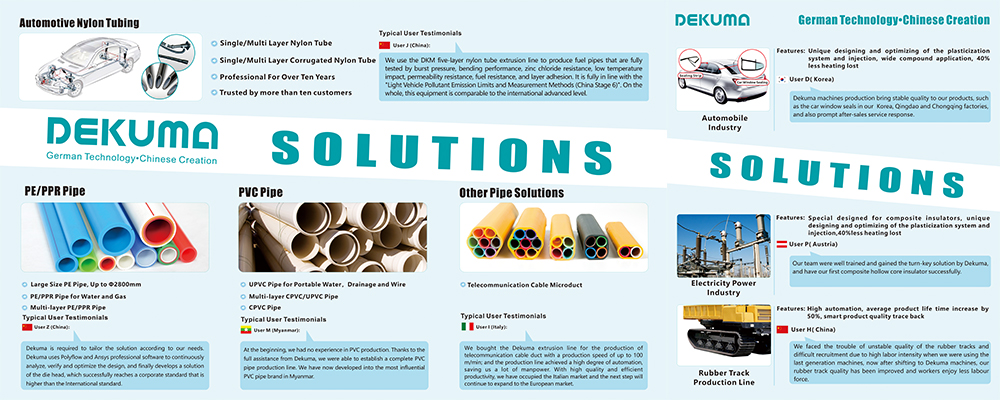

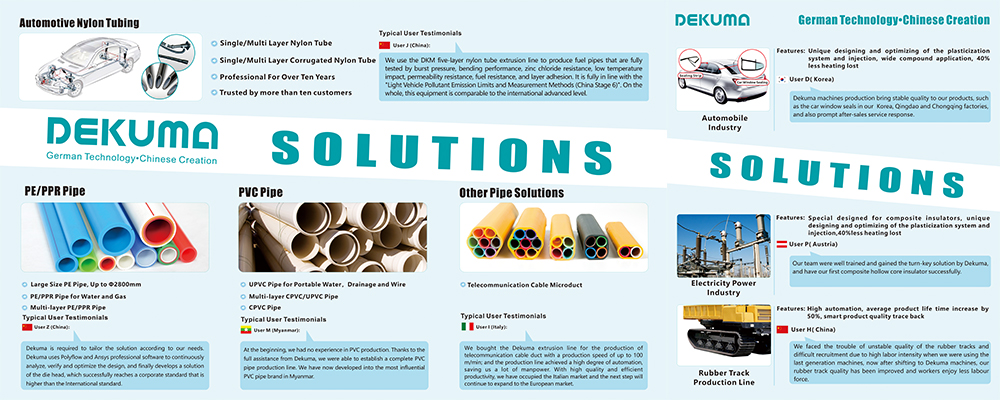

Tecomo — quality choice of rubber track production automation

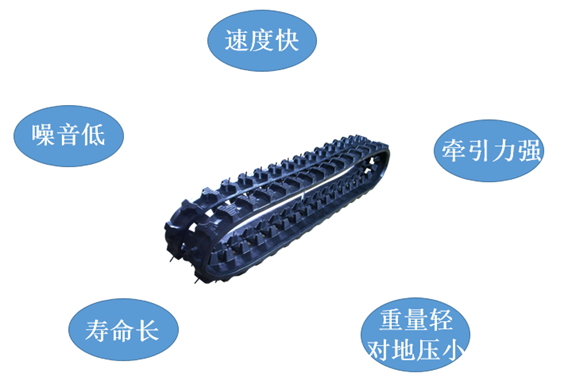

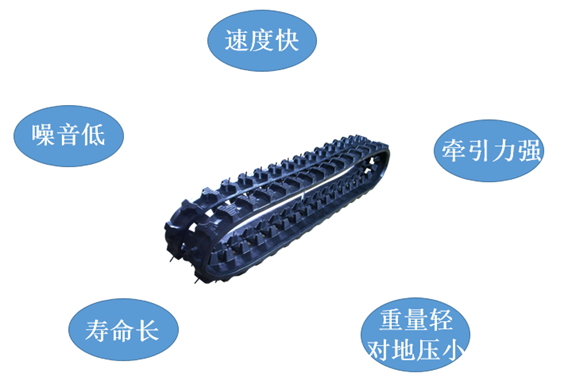

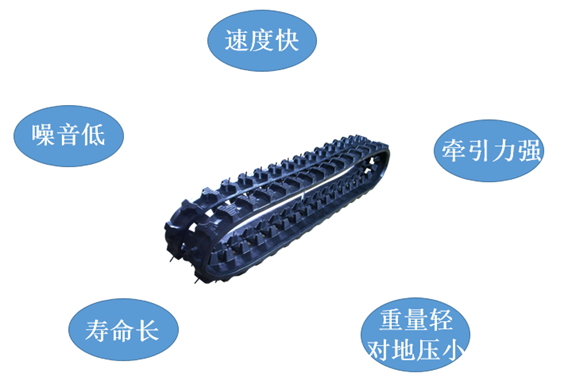

Rubber track is a kind of transportation equipment widely used in construction, agriculture, military and other industries. In modern society, rubber track provides a safer and more efficient way of transportation for many industries, which has the incomparable advantages of traditional metal track.

Although rubber track has many advantages, there are many problems in the production of rubber track. For example, the quality of the flat vulcanizing press used in the traditional rubber track production is uneven, inefficient and unstable, which often causes unnecessary waste of human resources, material resources and funds.

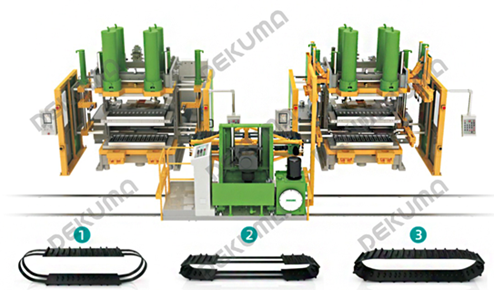

In order to solve this market problem, decamer launched a highly automated rubber crawler. This kind of rubber crawler is used in agricultural, engineering, military and other vehicle tracks. It can automatically load the tape, realize the automatic transportation of rubber materials, the automatic tension of steel wire rope, and the semi-automatic removal of products. Its automation level is far ahead of the peers, providing a solution with high efficiency, stability and reliability for the production of rubber crawler, and can effectively reduce the cost of manpower and capital, and solve many problems in the industry at one stroke.

In addition to the high degree of automation, the rubber track production line of decamer has many advantages:

Energy saving: in the process of vulcanization, there is no power consumption when the hydraulic pump is stopped, and there is no obvious decrease in mold locking;

Hydraulic precise control of multiple actions synchronization: accurate comparison and adjustment of the flow rate of the three pumps from 0-100% speed to achieve accurate synchronization of each action;

Prolonging product life: due to the ingenious combination of mold locking vulcanization unit and automatic tensioning steel belt device, the average service life of rubber track is increased by 50%;

Intelligent traceability of product quality: intelligent control system, ingenious control of various parameters, monitoring and control of multiple working conditions, and automatic storage of key parameters in the production process.

Professional team can provide personalized technical solutions for your project and provide reliable engineering technology. Tecomo has been working in the rubber machinery industry for many years, and its product technology, quality and service are obviously leading the industry level. If you want to find a solution for rubber track production, you should choose decamer, the spokesperson of high quality in the industry.

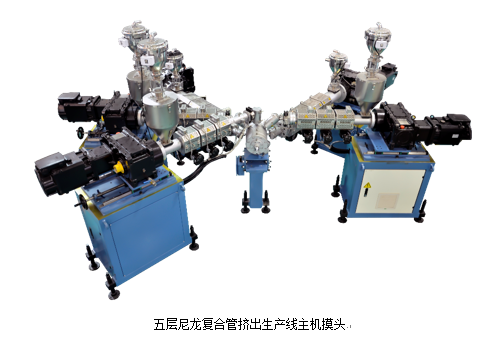

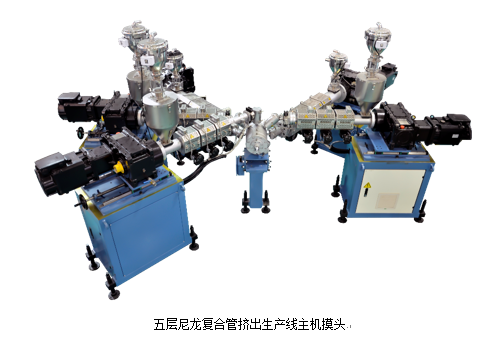

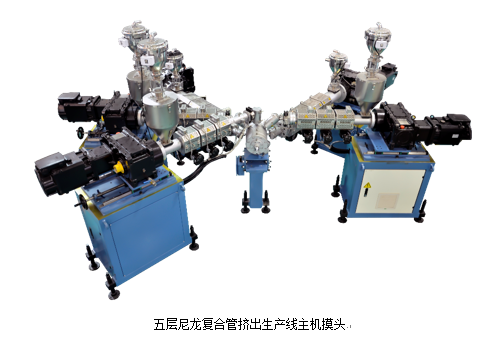

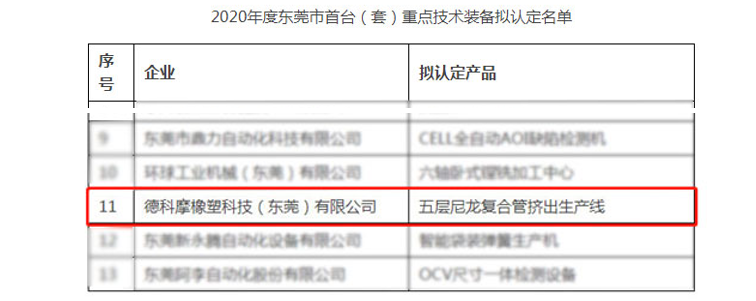

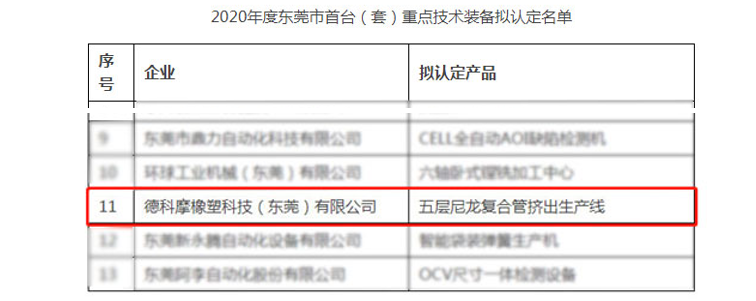

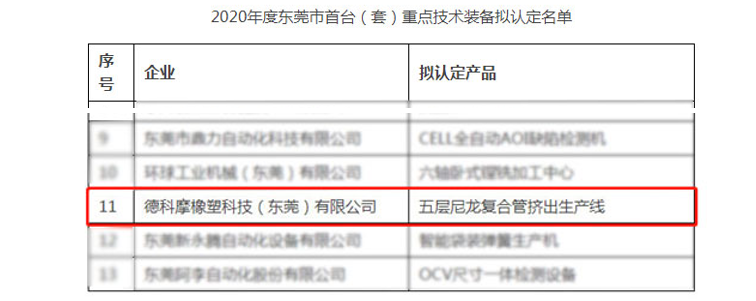

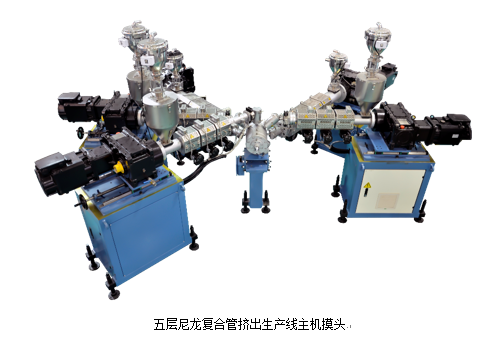

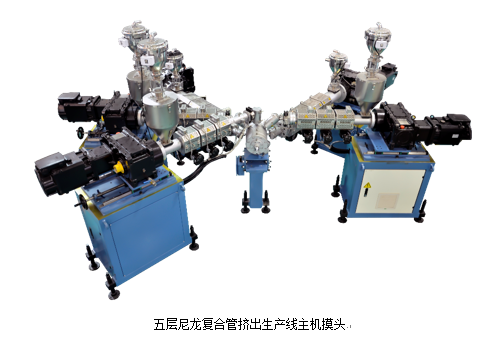

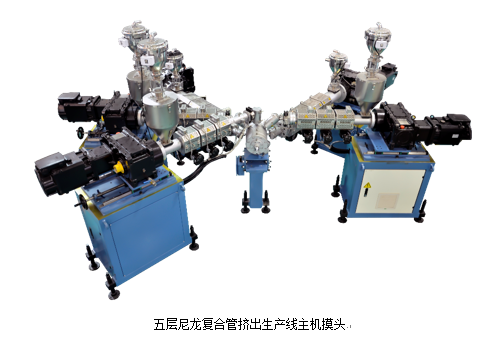

“Five layer nylon composite pipe extrusion production line” won the title of the first key technical equipment in Dongguan City in 2020

In order to accelerate the adjustment of Dongguan’s industrial structure, the transformation of kinetic energy and economic transformation, and promote the steady and good development of advanced equipment manufacturing enterprises, Dongguan Municipal Bureau of industry and information technology held the evaluation activity of Dongguan’s first (set) key technical equipment in 2020. After examination and confirmation, the “five layer nylon composite pipe extrusion production line” and other products of decomo rubber and Plastic Technology Co., Ltd. were identified as one of the first (set) key technical equipment in Dongguan City in 2020. The evaluation results are published on the following website of Dongguan Municipal Bureau of industry and information technology: https://im.dg.gov.cn/gkmlpt/content/3/3316/post_3316956.html#368.So far, the publicity period has ended.

The 5-layer nylon composite pipe extrusion production line of decomo is mainly used to produce automobile oil pipes conforming to the national standard 6. Decomo is the first manufacturer of such equipment in China, changing the situation that such products could only be imported from abroad in the past. There are two outstanding highlights in the five layer nylon composite pipe extrusion line of decamer. One is its extrusion molding process, which can keep the characteristics of various materials in the multi-channel process of the production process, so as to ensure the expected effect of the formed nylon pipe. The second is accuracy and stability. The thickness accuracy of each layer of material is ± 0.02-0.03mm, which can maintain stability in high-speed operation for a long time. The accuracy and stability are in a leading position in the industry, which is very consistent with the development requirements of industry 4.0.

Delcomo has been constantly improving its equipment and keeping its technology leading by combining its R & D experience and customers’ usage. Five layer nylon composite pipe extrusion production line won the “China machinery industry science and Technology Progress Award” in 2014, and this year it was recognized by the relevant departments of Dongguan City, which is the affirmation of the efforts of all staff of decamer. In the future, delcomo will continue to develop extrusion machinery technology and provide first-class extrusion equipment for users based on their needs.

Demo won the honor of “self manufacturing technology competition” in Dongguan in 2020

Recently, the list of winners of Dongguan modern manufacturing technology vocational skills competition in 2020 has been released. Four colleagues from the assembly department and the production department of our company stand out in the competition and have made great achievements. Among them, Liu Jie won the third prize of “assembly fitter”, and long Zongyuan, Wang Feng and Liu Donghui won the excellent award of “assembly fitter”.

Dongguan modern manufacturing technology vocational skills competition is based on the characteristics of industrial development of Dongguan City, Dongguan Municipal Bureau of human resources and social security selects the occupation (type of work) with wide coverage, strong versatility, advanced technology, more employees and great influence as the project competition, aiming to further improve the skill level of enterprise employees and accelerate the cultivation of high skilled talents. A total of 309 contestants competed on the same stage in this competition, including various theoretical knowledge and practical exercises. It can be said that the dragon and the tiger are fighting each other and are in full swing.

Dongguan Municipal Bureau of human resources and social security will present honors to the winners and present them with certificates and prizes. Congratulations again! I believe that this competition will encourage more colleagues to work hard on their posts, improve their technical level, and strive to become technical experts and skill pacesetters.

K SHOW 2019

DEKUMA will be showing our latest Extrusion and Rubber Injection machines and technology at Hall 15A37 in K show 2019.

We are going to display rubber injection molding machine for auto sealing and single screw extruder.

Come visit us in K 2019!

We look forward to welcoming you.

DEKUMA Attending CIGRE Technical Exhibition 2018

Exhibition: CIGRE

Technical Exhibition 2018,INTERNATIONAL COUNCIL ON LARGE ELECTRIC SYSTEMS

Date: 26 – 31, AUG 2018

Place:Palais des Congrès, 2 Place de la Porte Maillot, Paris – France

Booth: 169B

2017 INMR WORLD CONGRESS

2017 INMR WORLD CONGRESS

Date: Nov.5-8,2017

Location: Meliã Hotel & Conference Center Barcelona-Sitges, Spain

Booth: 16

Exhibitor: DEKUMA RUBBER INJECTION MACHINE

2015 INMR WORLD CONGRESS

Time: Oct 18-21, 2015

Location: Westin Grand Hotel, Munich, Germany

Booth: F6 & F7